Page 604 - Industrial Tools Catalog (1)

P. 604

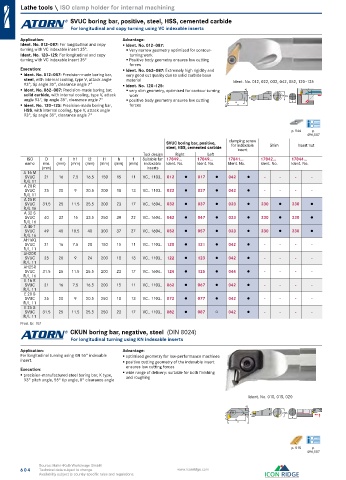

Lathe tools \ ISO clamp holder for internal machining

SVUC boring bar, positive, steel, HSS, cemented carbide

For longitudinal and copy turning using VC indexable inserts

Application: Advantage:

Ident. No. 012–087: For longitudinal and copy Ident. No. 012–087:

turning with VC indexable insert 35°. Very narrow geometry optimised for contour-

Ident. No. 120–125: For longitudinal and copy turning work

turning with VC indexable insert 35° Positive body geometry ensures low cutting

forces

Execution: Ident. No. 062–087: Extremely high rigidity and

Ident. No. 012–057: Precision-made boring bar, very good cut quality due to solid carbide base

steel, with internal cooling, type V, attack angle material Ident. No. 012, 022, 032, 042, 052, 120–125

93°, tip angle 35°, clearance angle 7° Ident. No. 120–125:

Ident. No. 062–087: Precision-made boring bar, very slim geometry, optimised for contour turning d

solid carbide, with internal cooling, type V, attack work ØDmin.

angle 93°, tip angle 35°, clearance angle 7° positive body geometry ensures low cutting f h1 h

Ident. No. 120–125: Precision-made boring bar, forces 30° l2 l1

HSS, with internal cooling, type V, attack angle

93°, tip angle 35°, clearance angle 7°

p. 546 p.

496,587

SVUC boring bar, positive, clamping screw

steel, HSS, cemented carbide for indexable Shim Insert nut

insert

Tool design Right Left

ISO D d h1 l2 l1 h f Suitable for 17849... 17849... 17841... 17842... 17844...

name min. (mm) (mm) (mm) (mm) (mm) (mm) indexable Ident. No. Ident. No. Ident. No. Ident. No. Ident. No.

(mm) inserts

A 16 M

SVUC 21 16 7.5 16.5 150 15 11 VC.. 1103.. 012 ● 017 ● 042 ● - - - -

R/L 11

A 20 R

SVUC 25 20 9 20.5 200 18 13 VC.. 1103.. 022 ● 027 ● 042 ● - - - -

R/L 11

A 25 R

SVUC 31.5 25 11.5 25.5 200 23 17 VC.. 1604.. 032 ● 037 ● 023 ● 230 ● 230 ●

R/L 16

A 32 S

SVUC 40 32 15 33.5 250 30 22 VC.. 1604.. 042 ● 047 ● 023 ● 230 ● 230 ●

R/L 16

A 40 T

SVUC 49 40 18.5 40 300 37 27 VC.. 1604.. 052 ● 057 ● 023 ● 230 ● 230 ●

R/L 16

AH16Q

SVUC 21 16 7.5 20 180 15 11 VC.. 1103.. 120 ● 121 ● 042 ● - - - -

R/L 11

AH20R

SVUC 25 20 9 24 200 18 13 VC.. 1103.. 122 ● 123 ● 042 ● - - - -

R/L 11

AH25R

SVUC 31.5 25 11.5 25.5 200 23 17 VC.. 1604.. 124 ● 125 ● 044 ● - - - -

R/L 16

E 16 R

SVUC 21 16 7.5 16.5 200 15 11 VC.. 1103.. 062 ● 067 ● 042 ● - - - -

R/L 11

E 20 S

SVUC 25 20 9 20.5 250 18 13 VC.. 1103.. 072 ● 077 ● 042 ● - - - -

R/L 11

E 25 S

SVUC 31.5 25 11.5 25.5 250 23 17 VC.. 1103.. 082 ● 087 ○ 042 ● - - - -

R/L 11

Prod. Gr. 107

CKUN boring bar, negative, steel (DIN 8024)

For longitudinal turning using KN indexable inserts

Application: Advantage:

For longitudinal turning using KN 55° indexable optimised geometry for low-performance machines

insert. positive cutting geometry of the indexable insert

Execution: ensures low cutting forces

precision-manufactured steel boring bar, K type, wide range of delivery: suitable for both finishing

and roughing

93° pitch angle, 55° tip angle, 0° clearance angle

Ident. No. 010, 015, 020

d

ØDmin.

h1

f

h

l2

l1

p. 510 p.

496,587

Source: Hahn+Kolb Werkzeuge GmbH

604 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.