Page 657 - Industrial Tools Catalog (1)

P. 657

Lathe tools \ Parting tools

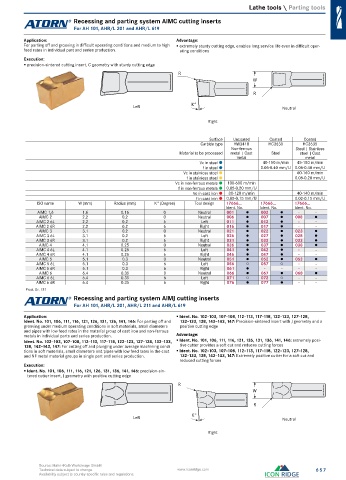

Recessing and parting system AIMC cutting inserts

For AH 101, AHR/L 201 and AHR/L 619

Application: Advantage:

For parting off and grooving in difficult operating conditions and medium to high extremely sturdy cutting edge, enables long service life even in difficult oper-

feed rates in individual part and series production. ating conditions

Execution:

precision-sintered cutting insert, C geometry with sturdy cutting edge

R

W

R

Left K° Neutral

Right

Surface Uncoated Coated Coated

Carbide type HW3410 HC3630 HC3635

Non-ferrous Steel | Stainless

Material to be processed metal | Cast Steel steel | Cast

metal metal

Vc in steel 40-150 m/min 45-180 m/min

f in steel 0.05-0.40 mm/U 0.05-0.40 mm/U

Vc in stainless steel 60-160 m/min

f in stainless steel 0.05-0.20 mm/U

Vc in non-ferrous metals 100-600 m/min

f in non-ferrous metals 0.05-0.20 mm/U

Vc in cast iron 80-120 m/min 40-140 m/min

f in cast iron 0.05-0.15 mm/U 0.02-0.15 mm/U

ISO name W (mm) Radius (mm) K° (Degree) Tool design 17666... 17666... 17666...

Ident. No. Ident. No. Ident. No.

AIMC 1,6 1.6 0.16 0 Neutral 001 ● 002 ● - -

AIMC 2 2.2 0.2 0 Neutral 006 ● 007 ● 008 ●

AIMC 2 6L 2.2 0.2 6 Left 011 ● 012 ● - -

AIMC 2 6R 2.2 0.2 6 Right 016 ● 017 ● - -

AIMC 3 3.1 0.2 0 Neutral 021 ● 022 ● 023 ●

AIMC 3 6L 3.1 0.2 6 Left 026 ● 027 ● 028 ●

AIMC 3 6R 3.1 0.2 6 Right 031 ● 032 ● 033 ●

AIMC 4 4.1 0.25 0 Neutral 036 ● 037 ● 038 ●

AIMC 4 6L 4.1 0.25 6 Left 041 ● 042 ● - -

AIMC 4 6R 4.1 0.25 6 Right 046 ● 047 ● - -

AIMC 5 5.1 0.3 0 Neutral 051 ● 052 ● 053 ●

AIMC 5 6L 5.1 0.3 6 Left 056 ○ 057 ○ - -

AIMC 5 6R 5.1 0.3 6 Right 061 ● - - - -

AIMC 6 6.4 0.35 0 Neutral 066 ● 067 ● 068 ●

AIMC 6 6L 6.4 0.35 6 Left 071 ○ 072 ○ - -

AIMC 6 6R 6.4 0.35 6 Right 076 ● 077 ● - -

Prod. Gr. 181

Recessing and parting system AIMJ cutting inserts

For AH 101, AHR/L 201, AHR/L 211 and AHR/L 619

Application: Ident. No. 102–103, 107–108, 112–113, 117–118, 122–123, 127–128,

Ident. No. 101, 106, 111, 116, 121, 126, 131, 136, 141, 146: For parting off and 132–133, 138, 142–143, 147: Precision-sintered insert with J geometry and a

grooving under medium operating conditions in soft materials, small diameters positive cutting edge

and pipes with low feed rates in the material group of cast iron and non-ferrous

metals in individual parts and series production. Advantage:

Ident. No. 102–103, 107–108, 112–113, 117–118, 122–123, 127–128, 132–133, Ident. No. 101, 106, 111, 116, 121, 126, 131, 136, 141, 146: extremely posi-

138, 142–143, 147: For cutting off and plunging under average machining condi- tive cutter provides a soft cut and reduces cutting forces

tions in soft materials, small diameters and pipes with low feed rates in the cast Ident. No. 102–103, 107–108, 112–113, 117–118, 122–123, 127–128,

and NF metal material groups in single part and series production. 132–133, 138, 142–143, 147: Extremely positive cutter for a soft cut and

reduced cutting forces

Execution:

Ident. No. 101, 106, 111, 116, 121, 126, 131, 136, 141, 146: precision-sin-

tered cutter insert, J geometry with positive cutting edge

R

W

R

Left K° Neutral

Right

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 657

Availability subject to country specific rules and regulations.