Page 668 - Industrial Tools Catalog (1)

P. 668

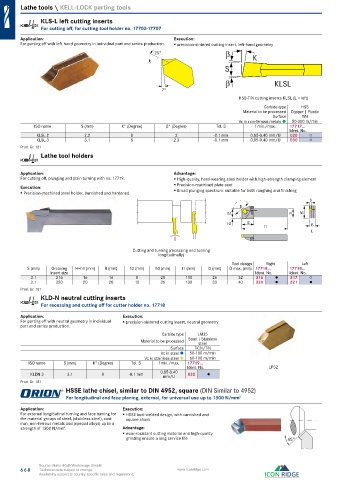

Lathe tools \ KELL-LOCK parting tools

KLS-L left cutting inserts

For cutting off, for cutting tool holder no. 17702-17707

Application: Execution:

For parting off with left-hand geometry in individual part and series production. precision-sintered cutting insert, left-hand geometry

25°

K

S

KLSL

7°

HSS-TiN cutting inserts KLSL (L = left)

Carbide type HSS

Material to be processed Copper | Plastic

Surface TiN

Vc in non-ferrous metals 50-300 m/min

ISO name S (mm) K° (Degree) β° (Degree) Tol. S f min./max. 17717...

Ident. No.

KLSL 2 2.2 8 2 -0.1 mm 0.05-0.40 mm/U 020 ○

KLSL 3 3.1 8 2.3 -0.1 mm 0.05-0.40 mm/U 030 ○

Prod. Gr. 181

Lathe tool holders

Application: Advantage:

For cutting off, plunging and plain turning with no. 17719. High-quality, hard-wearing steel holder with high-strength clamping element

Execution: Precision-machined plate seat

Precision-machined steel holder, burnished and hardened Broad plunging spectrum: suitable for both roughing and finishing

S

D

h1 H h3

h2 l2 B

l1

L

Cutting and turning (recessing and turning

longitudinally)

Tool design Right Left

S (mm) Grooving H=h1 (mm) B (mm) h2 (mm) h3 (mm) l1 (mm) l2 (mm) D max. (mm) 17718... 17718...

insert size Ident. No. Ident. No.

3.1 316 16 16 8 28 110 26 32 316 ● 317 ○

3.1 320 20 20 12 36 130 33 40 320 ● 321 ●

Prod. Gr. 181

KLD-N neutral cutting inserts

For recessing and cutting off for cutter holder no. 17718

Application: Execution:

For parting off with neutral geometry in individual precision-sintered cutting insert, neutral geometry

part and series production.

Carbide type LM35

Material to be processed Steel | Stainless

steel

Surface TiCN/TiN

Vc in steel 50-180 m/min

Vc in stainless steel 60-100 m/min

ISO name S (mm) K° (Degree) Tol. S f min./max. 17719...

Ident. No. LP32

KLDN 3 3.1 0 -0.1 mm 0.05-0.40 032 ●

mm/U

Prod. Gr. 181

HSSE lathe chisel, similar to DIN 4952, square (DIN Similar to 4952)

For longitudinal and face planing, external, for universal use up to 1300 N/mm 2

Application: Execution:

For external longitudinal turning and face turning for HSSE butt-welded design, with varnished and

the material groups of steel, (stainless steel), cast square shank

iron, non-ferrous metals and (special alloys) up to a

strength of 1300 N/mm . 2 Advantage:

wear-resistant cutting material and high-quality

grinding ensure a long service life 45°

Source: Hahn+Kolb Werkzeuge GmbH

668 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.