Page 74 - Industrial Tools Catalog (1)

P. 74

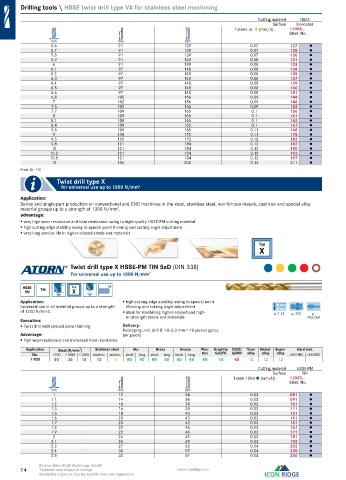

Drilling tools \ HSSE twist drill type VA for stainless steel machining

Cutting material HSSE

Surface Uncoated

f steinl. st. (mm/U) 11058...

Ident. No.

mm mm mm

5.6 91 139 0.07 127 ●

5.7 91 139 0.07 128 ●

5.8 91 139 0.07 130 ●

5.9 91 139 0.08 131 ●

6 91 139 0.08 133 ●

6.1 97 148 0.08 134 ●

6.2 97 148 0.08 135 ●

6.3 97 148 0.08 137 ●

6.4 97 148 0.08 139 ●

6.5 97 148 0.08 140 ●

6.6 97 148 0.08 141 ●

6.8 102 156 0.09 144 ●

7 102 156 0.09 146 ●

7.5 102 156 0.09 153 ●

7.7 109 165 0.1 156 ●

8 109 165 0.1 161 ●

8.1 109 165 0.1 162 ●

8.4 109 165 0.1 167 ●

8.5 109 165 0.11 168 ●

9 115 175 0.11 175 ●

9.5 115 175 0.12 182 ●

9.8 121 184 0.12 187 ●

10 121 184 0.12 190 ●

10.2 121 184 0.12 192 ●

10.5 121 184 0.13 197 ●

12 134 205 0.14 211 ●

Prod. Gr. 110

Twist drill type X

for universal use up to 1300 N/mm 2

Application:

Series and single-part production on conventional and CNC machines in the steel, stainless steel, non-ferrous metals, cast iron and special alloy

material groups up to a strength of 1300 N/mm . 2

advantage:

very high wear resistance and heat resistance owing to high-quality HSSE-PM cutting material

high cutting edge stability owing to special point thinning and cutting angle adjustment

very long service life in higher-alloyed steels and materials

Typ

X

Twist drill type X HSSE-PM TIN 5xD (DIN 338)

For universal use up to 1300 N/mm 2

HSSE- TiN Typ HA

PM X

5xD 118°

Application: high cutting edge stability owing to special point

Universal use in all material groups up to a strength thinning and cutting angle adjustment

of 1300 N/mm2. ideal for machining higher-alloyed and high- p. 7,14 p. 702 p.

Execution: er-strength steels and materials 702,769

Twist drill with special point thinning Delivery:

Packaging unit: drill Ø 1.0-6.0 mm = 10 pieces (price

Advantage: per piece)

high wear resistance and increased heat resistance

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11025 50 35 15 12 10 80 90 80 50 50 45 40 15 40 12 12 12

Cutting material HSSE-PM

Surface TiN

f steel 1000 (mm/U) 11025...

Ident. No.

mm mm mm

1 12 34 0.03 081 ●

1.1 14 36 0.03 091 ●

1.2 16 38 0.03 101 ●

1.3 16 38 0.03 111 ●

1.5 18 40 0.03 131 ●

1.6 20 43 0.03 141 ●

1.7 20 43 0.03 151 ●

1.8 22 46 0.03 161 ●

1.9 22 46 0.03 171 ●

2 24 49 0.03 181 ●

2.1 24 49 0.03 192 ●

2.2 27 53 0.04 202 ●

2.4 30 57 0.04 220 ●

2.5 30 57 0.04 230 ●

Source: Hahn+Kolb Werkzeuge GmbH

74 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.