Page 8 - Industrial Tools Catalog (1)

P. 8

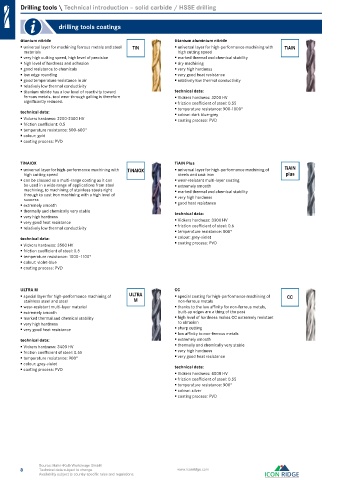

Drilling tools \ Technical introduction – solid carbide / HSSE drilling

drilling tools coatings

titanium nitride titanium aluminium nitride

universal layer for machining ferrous metals and steel TiN universal layer for high-performance machining with TiAlN

materials high cutting speed

very high cutting speed, high level of precision marked thermal and chemical stability

high level of hardness and adhesion dry machining

good resistance to chemicals very high hardness

low edge rounding very good heat resistance

good temperature resistance in air relatively low thermal conductivity

relatively low thermal conductivity

titanium nitride has a low level of reactivity toward technical data:

ferrous metals. tool wear through galling is therefore Vickers hardness: 3200 HV

significantly reduced. friction coefficient of steel: 0.55

temperature resistance: 900-1000°

technical data: colour: dark blue-grey

Vickers hardness: 2200-2300 HV coating process: PVD

friction coefficient: 0.5

temperature resistance: 500-600°

colour: gold

coating process: PVD

TiNAlOX TiAlN Plus

universal layer for high-performance machining with TiNAlOX universal layer for high-performance machining of TiAlN

high cutting speed steels and cast iron plus

can be classed as a multi-range coating as it can wear-resistant multi-layer coating

be used in a wide range of applications from steel extremely smooth

machining, to machining of stainless steels right marked thermal and chemical stability

through to cast iron machining with a high level of very high hardness

success

extremely smooth good heat resistance

thermally and chemically very stable technical data:

very high hardness

very good heat resistance Vickers hardness: 3300 HV

relatively low thermal conductivity friction coefficient of steel: 0.6

temperature resistance: 800°

technical data: colour: grey-violet

Vickers hardness: 3500 HV coating process: PVD

friction coefficient of steel: 0.5

temperature resistance: 1000–1100°

colour: violet-blue

coating process: PVD

ULTRA M CC

special layer for high-performance machining of ULTRA special coating for high-performance machining of CC

stainless steel and steel M non-ferrous metals

wear-resistant multi-layer material thanks to the low affinity for non-ferrous metals,

extremely smooth built-up edges are a thing of the past

marked thermal and chemical stability high level of hardness makes CC extremely resistant

very high hardness to abrasion

very good heat resistance sharp cutting

low affinity to non-ferrous metals

technical data: extremely smooth

Vickers hardness: 3400 HV thermally and chemically very stable

friction coefficient of steel: 0.55 very high hardness

temperature resistance: 900° very good heat resistance

colour: grey-violet technical data:

coating process: PVD

Vickers hardness: 4000 HV

friction coefficient of steel: 0.55

temperature resistance: 900°

colour: silver

coating process: PVD

Source: Hahn+Kolb Werkzeuge GmbH

8 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.