Page 82 - Industrial Tools Catalog (1)

P. 82

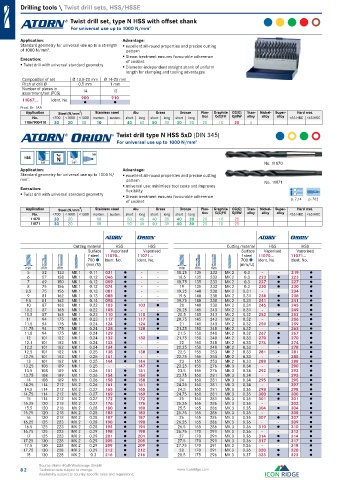

Drilling tools \ Twist drill sets, HSS/HSSE

Twist drill set, type N HSS with offset shank

For universal use up to 1000 N/mm 2

Application: Advantage:

Standard geometry for universal use up to a strength excellent all-round properties and precise cutting

of 1000 N/mm . 2 pattern

Execution: Steam treatment ensures favourable adherence

of coolant

Twist drill with universal standard geometry Diameter-independent straight shank of uniform

length for clamping and tooling advantages

Composition of set Ø 13.5-20 mm Ø 14-25 mm

Pitch of drill Ø 0.5 mm 1 mm

Number of pieces in 14 12

assortment/set (PCS)

11067... Ident. No. 900 910

●

●

Prod. Gr. 1AA

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11067900-910 30 20 10 10 8 40 60 50 30 30 20 20 10 20 4

Twist drill type N HSS 5xD (DIN 345)

For universal use up to 1000 N/mm 2

Typ MK

HSS N

5xD 118° No. 11070

Application: Advantage:

Standard geometry for universal use up to 1000 N/ excellent all-round properties and precise cutting

mm . 2 pattern No. 11071

Execution: universal use: minimises tool costs and improves

flexibility

Twist drill with universal standard geometry Steam treatment ensures favourable adherence

of coolant p. 7,14 p. 762

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11070 30 20 10 50 45 40 35 40 30 20 10 25

11071 30 20 10 50 45 40 35 40 30 20 10 25

Cutting material HSS HSS Cutting material HSS HSS

Surface Vaporised Vaporised Surface Vaporised Vaporised

f steel 11070... 11071... f steel 11070... 11071...

700 Ident. No. Ident. No. 700 Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm

5 52 133 MK 1 0.11 031 ● - - 18.25 135 233 MK 2 0.3 - - 219 ●

6 57 138 MK 1 0.12 046 ● - - 18.5 135 233 MK 2 0.3 223 ● 223 ●

7 69 150 MK 1 0.12 059 ● - - 18.75 135 233 MK 2 0.3 227 ● 227 ●

8 75 156 MK 1 0.12 074 ● - - 19 135 233 MK 2 0.3 230 ● 230 ●

8.5 75 156 MK 1 0.13 081 ● - - 19.25 140 238 MK 2 0.31 - - 234 ●

9 81 162 MK 1 0.13 088 ● - - 19.5 140 238 MK 2 0.31 238 ● 238 ●

9.5 81 162 MK 1 0.14 095 ● - - 19.75 140 238 MK 2 0.31 241 ● 241 ●

10 87 168 MK 1 0.22 103 ● 103 ● 20 140 238 MK 2 0.31 245 ● 245 ●

10.2 87 168 MK 1 0.22 105 ● - - 20.25 145 243 MK 2 0.31 - - 249 ●

10.5 87 168 MK 1 0.23 110 ● 110 ● 20.5 145 243 MK 2 0.32 252 ● 252 ●

11 94 175 MK 1 0.23 117 ● 117 ● 20.75 145 243 MK 2 0.32 - - 256 ●

11.5 94 175 MK 1 0.24 124 ● 124 ● 21 145 243 MK 2 0.32 259 ● 259 ●

11.75 94 175 MK 1 0.24 128 ● 128 ● 21.25 150 248 MK 2 0.32 - - 263 ●

11.8 94 175 MK 1 0.24 129 ● - - 21.5 150 248 MK 2 0.32 267 ● 267 ●

12 101 182 MK 1 0.24 132 ● 132 ● 21.75 150 248 MK 2 0.33 270 ● 270 ●

12.1 101 182 MK 1 0.24 133 ● - - 22 150 248 MK 2 0.33 274 ● 274 ●

12.2 101 182 MK 1 0.24 134 ● - - 22.25 150 248 MK 2 0.33 - - 278 ●

12.5 101 182 MK 1 0.25 138 ● 138 ● 22.5 155 253 MK 2 0.33 281 ● 281 ●

12.75 101 182 MK 1 0.25 141 ● - - 22.75 155 253 MK 2 0.33 - - 285 ●

13 101 182 MK 1 0.25 144 ● 144 ● 23 155 253 MK 2 0.33 288 ● 288 ●

13.25 108 189 MK 1 0.25 - - 147 ● 23.25 155 276 MK 3 0.34 - - 290 ●

13.5 108 189 MK 1 0.26 151 ● 151 ● 23.5 155 276 MK 3 0.34 292 ● 292 ●

13.75 108 189 MK 1 0.26 154 ● 154 ● 23.75 160 281 MK 3 0.34 - - 293 ●

14 108 189 MK 1 0.26 158 ● 158 ● 24 160 281 MK 3 0.34 295 ● 295 ●

14.25 114 212 MK 2 0.26 161 ● 161 ● 24.25 160 281 MK 3 0.34 - - 297 ●

14.5 114 212 MK 2 0.27 165 ● 165 ● 24.5 160 281 MK 3 0.35 298 ● 298 ●

14.75 114 212 MK 2 0.27 169 ● 169 ● 24.75 160 281 MK 3 0.35 300 ● 300 ●

15 114 212 MK 2 0.27 172 ● 172 ● 25 160 281 MK 3 0.35 301 ● 301 ●

15.25 120 218 MK 2 0.27 176 ● 176 ● 25.25 165 286 MK 3 0.35 - - 302 ●

15.5 120 218 MK 2 0.28 180 ● 180 ● 25.5 165 286 MK 3 0.35 304 ● 304 ●

15.75 120 218 MK 2 0.28 183 ● 183 ● 25.75 165 286 MK 3 0.35 - - 305 ●

16 120 218 MK 2 0.28 187 ● 187 ● 26 165 286 MK 3 0.35 307 ● 307 ●

16.25 125 223 MK 2 0.28 190 ● 190 ● 26.25 165 286 MK 3 0.36 - - 309 ●

16.5 125 223 MK 2 0.28 194 ● 194 ● 26.5 165 286 MK 3 0.36 310 ● 310 ●

16.75 125 223 MK 2 0.29 198 ● 198 ● 26.75 170 291 MK 3 0.36 - - 312 ●

17 125 223 MK 2 0.29 201 ● 201 ● 27 170 291 MK 3 0.36 314 ● 314 ●

17.25 130 228 MK 2 0.29 205 ● 205 ● 27.5 170 291 MK 3 0.36 317 ● 317 ●

17.5 130 228 MK 2 0.29 209 ● 209 ● 27.75 170 291 MK 3 0.36 - - 318 ●

17.75 130 228 MK 2 0.29 212 ● 212 ● 28 170 291 MK 3 0.36 320 ● 320 ●

18 130 228 MK 2 0.3 216 ● 216 ● 28.5 175 296 MK 3 0.37 323 ● 323 ●

Source: Hahn+Kolb Werkzeuge GmbH

82 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.