Page 88 - Industrial Tools Catalog (1)

P. 88

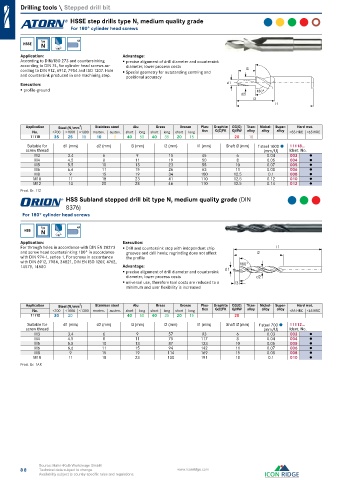

Drilling tools \ Stepped drill bit

HSSE step drills type N, medium quality grade

For 180° cylinder head screws

Typ HA

HSSE N

118°

Application: Advantage:

According to DIN/ISO 273 and countersinking precise alignment of drill diameter and countersink

according to DIN 74, for cylinder head screws ac- diameter, lower process costs

cording to DIN 912, 6912, 7984 and ISO 1207. Hole Special geometry for outstanding centring and l3

and countersink produced in one machining step. positional accuracy

Execution: d1

profile-ground 180°

d2

l2

l1

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11118 35 25 10 10 8 40 50 40 35 20 15 20 10

Suitable for d1 (mm) d2 (mm) l3 (mm) l2 (mm) l1 (mm) Shaft Ø (mm) f steel 1000 11118...

screw thread (mm/U) Ident. No.

M3 3.4 6 9 15 45 6 0.04 003 ●

M4 4.5 8 11 19 50 8 0.05 004 ●

M5 5.5 10 13 23 55 10 0.07 005 ●

M6 6.6 11 15 26 63 11 0.08 006 ●

M8 9 15 19 34 100 12.5 0.1 008 ●

M10 11 18 23 41 110 12.5 0.12 010 ●

M12 14 20 28 46 110 12.5 0.14 012 ●

Prod. Gr. 112

HSS Subland stepped drill bit type N, medium quality grade (DIN

8376)

For 180° cylinder head screws

Typ HA

HSS N

118°

Application: Execution:

For through holes in accordance with DIN EN 20273 Drill and countersink step with independent chip l1

and screw head countersinking 180° in accordance grooves and drill heels; regrinding does not affect l2

with DIN 974-1, series 1. For screws in accordance the profile

with DIN 6912, 7984, 34821, DIN EN ISO 1207, 4762, 180°

14579, 14580 Advantage:

precise alignment of drill diameter and countersink d1

diameter, lower process costs d2

universal use, therefore tool costs are reduced to a l3

minimum and user flexibility is increased

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11112 30 20 40 50 40 35 20 15 20

Suitable for d1 (mm) d2 (mm) l3 (mm) l2 (mm) l1 (mm) Shaft Ø (mm) f steel 700 11112...

screw thread (mm/U) Ident. No.

M3 3.4 6 9 57 93 6 0.03 003 ●

M4 4.5 8 11 75 117 8 0.04 004 ●

M5 5.5 10 13 87 133 10 0.05 005 ●

M6 6.6 11 15 94 142 11 0.07 006 ●

M8 9 15 19 114 169 15 0.08 008 ●

M10 11 18 23 130 191 18 0.1 010 ●

Prod. Gr. 1AR

Source: Hahn+Kolb Werkzeuge GmbH

88 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.