Page 111 - Icon Ridge Painting, Plastering & Drywall Catalog

P. 111

Cutting, Sanding, Sawing, Surface Treatment

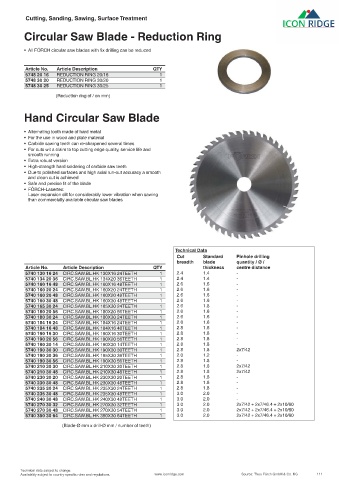

Circular Saw Blade - Reduction Ring

• All FÖRCH circular saw blades with fix drilling can be reduced

Article No. Article Description QTY

5748 20 16 REDUCTION RING 20/16 1

5748 30 20 REDUCTION RING 30/20 1

5748 30 25 REDUCTION RING 30/25 1

(Reduction ring of / on mm)

Hand Circular Saw Blade

• Alternating tooth made of hard metal

• For the use in wood and plate material

• Carbide sawing teeth can re-sharpened several times

• For cuts wit a claim to top cutting edge quality, service life and

smooth running

• Extra robust version

• High-strength hard soldering of carbide saw teeth

• Due to polished surfaces and high axial run-out accuracy a smooth

and clean cut is achieved

• Safe and precise fit of the blade

• FÖRCH-Lasertec:

Laser expansion slit for considerably lower vibration when sawing

than commercially available circular saw blades

Technical Data

Cut Standard Pinhole drilling

breadth blade quantity / Ø /

Article No. Article Description QTY thickness centre distance

5740 130 16 24 CIRC.SAW.BL.HK 130X16 24TEETH 1 2.4 1.4 -

5740 134 20 36 CIRC.SAW.BL.HK 134X20 36TEETH 1 2.4 1.4 -

5740 160 16 48 CIRC.SAW.BL.HK 160X16 48TEETH 1 2.6 1.6 -

5740 160 20 24 CIRC.SAW.BL.HK 160X20 24TEETH 1 2.6 1.6 -

5740 160 20 48 CIRC.SAW.BL.HK 160X20 48TEETH 1 2.6 1.6 -

5740 160 30 48 CIRC.SAW.BL.HK 160X30 48TEETH 1 2.6 1.6 -

5740 165 30 24 CIRC.SAW.BL.HK 165X30 24TEETH 1 2.6 1.8 -

5740 180 20 56 CIRC.SAW.BL.HK 180X20 56TEETH 1 2.6 1.6 -

5740 180 30 24 CIRC.SAW.BL.HK 180X30 24TEETH 1 2.6 1.6 -

5740 184 16 24 CIRC.SAW.BL.HK 184X16 24TEETH 1 2.6 1.6 -

5740 184 16 48 CIRC.SAW.BL.HK 184X16 48TEETH 1 2.8 1.8 -

5740 190 16 30 CIRC.SAW.BL.HK 190X16 30TEETH 1 2.8 1.8 -

5740 190 20 56 CIRC.SAW.BL.HK 190X20 56TEETH 1 2.8 1.8 -

5740 190 30 14 CIRC.SAW.BL.HK 190X30 14TEETH 1 2.8 1.8 -

5740 190 30 30 CIRC.SAW.BL.HK 190X30 30TEETH 1 2.8 1.8 2x7/42

5740 190 30 36 CIRC.SAW.BL.HK 195X30 36TEETH 1 2.0 1.2 -

5740 190 30 56 CIRC.SAW.BL.HK 190X30 56TEETH 1 2.8 1.8 -

5740 210 30 30 CIRC.SAW.BL.HK 210X30 30TEETH 1 2.8 1.8 2x7/42

5740 210 30 48 CIRC.SAW.BL.HK 210X30 48TEETH 1 2.8 1.8 2x7/42

5740 230 30 20 CIRC.SAW.BL.HK 230X30 20TEETH 1 2.8 1.8 -

5740 230 30 48 CIRC.SAW.BL.HK 230X30 48TEETH 1 2.8 1.8 -

5740 235 30 24 CIRC.SAW.BL.HK 235X30 24TEETH 1 2.8 1.8 -

5740 235 30 48 CIRC.SAW.BL.HK 235X30 48TEETH 1 3.0 2.0 -

5740 240 30 48 CIRC.SAW.BL.HK 240X30 48TEETH 1 3.0 2.0 -

5740 270 30 32 CIRC.SAW.BL.HK 270X30 32TEETH 1 3.0 2.0 2x7/42 + 2x7/46.4 + 2x10/60

5740 270 30 48 CIRC.SAW.BL.HK 270X30 54TEETH 1 3.0 2.0 2x7/42 + 2x7/46.4 + 2x10/60

5740 350 30 64 CIRC.SAW.BL.HK 350X30 64TEETH 1 3.0 2.0 2x7/42 + 2x7/46.4 + 2x10/60

(Blade-Ø mm x drill-Ø mm / number of teeth)

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 111