Page 178 - Icon Ridge Painting, Plastering & Drywall Catalog

P. 178

Hand tools

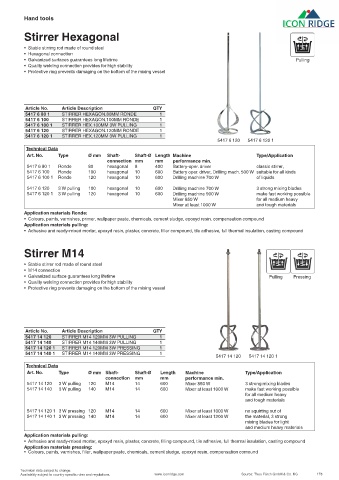

Stirrer Hexagonal

• Stable stirring rod made of round steel

• Hexagonal connection

• Galvanized surfaces guarantees long lifetime Pulling

• Quality welding connection provides for high stability

• Protective ring prevents damaging on the bottom of the mixing vessel

Article No. Article Description QTY

5417 6 80 1 STIRRER HEXAGON.80MM RONDE 1

5417 6 100 STIRRER HEXAGON.100MM RONDE 1

5417 6 100 1 STIRRER HEX.100MM 3W PULLING 1

5417 6 120 STIRRER HEXAGON.120MM RONDE 1

5417 6 120 1 STIRRER HEX.120MM 3W PULLING 1

5417 6 120 5417 6 120 1

Technical Data

Art. No. Type Ø mm Shaft- Shaft-Ø Length Machine Type/Application

connection mm mm performance min.

5417 6 80 1 Ronde 80 hexagonal 8 400 Battery-oper. driver classic stirrer,

5417 6 100 Ronde 100 hexagonal 10 600 Battery oper. driver, Drilling mach. 500 W suitable for all kinds

5417 6 100 1 Ronde 120 hexagonal 10 600 Drilling machine 700 W of liquids

5417 6 120 3 W pulling 100 hexagonal 10 600 Drilling machine 700 W 3 strong mixing blades

5417 6 120 1 3 W pulling 120 hexagonal 10 600 Drilling machine 900 W make fast working possible

Mixer 850 W for all medium heavy

Mixer at least 1000 W and tough materials

Application materials Ronde:

• Colours, paints, varnishes, primer, wallpaper paste, chemicals, cement sludge, epoxyd resin, compensation compound

Application materials pulling:

• Adhesive and ready-mixed mortar, epoxyd resin, plaster, concrete, filler compound, tile adhesive, full thermal insulation, casting compound

Stirrer M14

• Stable stirrer rod made of round steel

• M14 connection

• Galvanized surface guarantees long lifetime Pulling Pressing

• Quality welding connection provides for high stability

• Protective ring prevents damaging on the bottom of the mixing vessel

Article No. Article Description QTY

5417 14 120 STIRRER M14 120MM 3W PULLING 1

5417 14 140 STIRRER M14 140MM 3W PULLING 1

5417 14 120 1 STIRRER M14 120MM 3W PRESSING 1

5417 14 140 1 STIRRER M14 140MM 3W PRESSING 1

5417 14 120 5417 14 120 1

Technical Data

Art. No. Type Ø mm Shaft- Shaft-Ø Length Machine Type/Application

connection mm mm performance min.

5417 14 120 3 W pulling 120 M14 14 600 Mixer 850 W 3 strong mixing blades

5417 14 140 3 W pulling 140 M14 14 600 Mixer at least 1000 W make fast working possible

for all medium heavy

and tough materials

5417 14 120 1 3 W pressing 120 M14 14 600 Mixer at least 1000 W no squirting out of

5417 14 140 1 3 W pressing 140 M14 14 600 Mixer at least 1200 W the material, 3 strong

mixing blades for light

and medium heavy materials

Application materials pulling:

• Adhesive and ready-mixed mortar, epoxyd resin, plaster, concrete, filling compound, tile adhesive, full thermal insulation, casting compound

Application materials pressing:

• Colours, paints, varnishes, filler, wallpaper paste, chemicals, cement sludge, epoxyd resin, compensation comound

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 178