Page 492 - Icon Ridge Automotive & Truck Catalog

P. 492

Hand tools

Mebux® thread inserts

Application - Metric thread

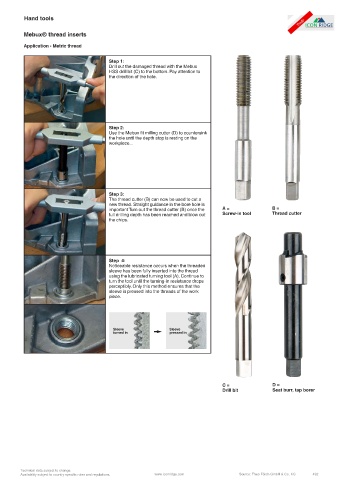

Step 1:

Drill out the damaged thread with the Mebux

HSS drill bit (C) to the bottom. Pay attention to

the direction of the hole.

Step 2:

Use the Mebux fit milling cutter (D) to countersink

the hole until the depth stop is resting on the

workpiece. .

Step 3:

The thread cutter (B) can now be used to cut a

new thread. Straight guidance in the bore hole is

important Turn out the thread cutter (B) once the A = B =

full drilling depth has been reached and blow out Screw-in tool Thread cutter

the chips.

Step 4:

Noticeable resistance occurs when the threaded

sleeve has been fully inserted into the thread

using the lubricated turning tool (A). Continue to

turn the tool until the turning-in resistance drops

perceptibly. Only this method ensures that the

sleeve is pressed into the threads of the work

piece.

Sleeve Sleeve

turned in pressed in

C = D =

Drill bit Seat burr, tap borer

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 492