Page 101 - Icon Ridge Presents ATORN

P. 101

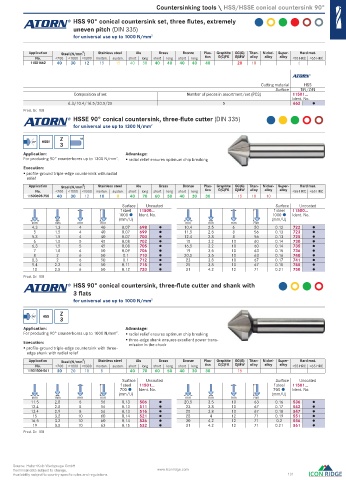

Countersinking tools \ HSS/HSSE conical countersink 90°

HSS 90° conical countersink set, three fl utes, extremely

uneven pitch ( DIN 335 )

for universal use up to 1000 N/mm 2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11501662 40 30 12 15 15 40 50 40 40 40 40 40 20 10 6

Cutting material HSS

Surface TiN/ZrN

Composition of set Number of pieces in assortment/set (PCS) 11501...

Ident. No.

6.3/10.4/16.5/20.5/25 5 662

Prod. Gr. 1EB

HSSE 90° conical countersink, three-fl ute cutter ( DIN 335 )

for universal use up to 1300 N/mm 2

Z HA

HSSE

3

Application: Advantage:

For producing 90° counterbores up to 1300 N/mm . 2 radial relief ensures optimum chip breaking

Execution:

profi le-ground triple-edge countersink with radial

relief

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11500698-750 40 30 12 10 8 40 70 60 50 40 30 30 15 10 10

Surface Uncoated Surface Uncoated

f steel 11500... f steel 11500...

1000 Ident. No. 1000 Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

4.3 1.3 4 40 0.07 698 10.4 2.5 6 50 0.12 722

5 1.5 4 40 0.07 699 11.5 2.8 8 56 0.13 723

5.3 1.5 4 40 0.07 700 12.4 2.8 8 56 0.13 725

6 1.5 5 45 0.08 702 15 3.2 10 60 0.14 730

6.3 1.5 5 45 0.08 705 16.5 3.2 10 60 0.14 735

7 1.8 6 50 0.09 706 19 3.5 10 63 0.15 736

8 2 6 50 0.1 710 20.5 3.5 10 63 0.16 740

8.3 2 6 50 0.1 712 23 3.8 10 67 0.17 741

9.4 2.2 6 50 0.11 715 25 3.8 10 67 0.18 745

10 2.5 6 50 0.12 720 31 4.2 12 71 0.21 750

Prod. Gr. 1EB

HSS 90° conical countersink, three-fl ute cutter and shank with

3 fl ats

for universal use up to 1000 N/mm 2

Z

HSS

3

Application: Advantage:

For producing 90° counterbores up to 1000 N/mm . 2 radial relief ensures optimum chip breaking

Execution: three-edge shank ensures excellent power trans-

mission in the chuck

profi le-ground triple-edge countersink with three-

edge shank with radial relief

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11501506-561 30 20 10 8 40 70 60 50 40 30 30 15

Surface Uncoated Surface Uncoated

f steel 11501... f steel 11501...

700 Ident. No. 700 Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

11.5 2.8 8 56 0.13 506 20.5 3.5 10 63 0.16 536

12.4 2.8 8 56 0.13 511 23 3.8 10 67 0.17 542

13.4 2.9 8 56 0.13 516 25 3.8 10 67 0.18 547

15 3.2 10 60 0.14 521 28 4 12 71 0.19 551

16.5 3.2 10 60 0.14 526 30 4.2 12 71 0.2 556

19 3.5 10 63 0.15 532 31 4.2 12 71 0.21 561

Prod. Gr. 1EB

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 101

0126_EN_2018_KERN[21846802]-k.indd 127 12/17/2018 3:31:09 PM