Page 127 - Icon Ridge Presents ATORN

P. 127

Reaming tools \ Technical introduction – reaming

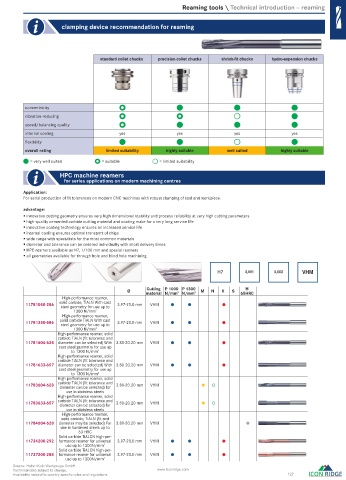

clamping device recommendation for reaming

standard collet chucks precision collet chucks shrink-fi t chucks hydro-expansion chucks

concentricity

vibration-reducing

speed/balancing quality

internal cooling yes yes yes yes

fl exibility

overall rating limited suitability highly suitable well suited highly suitable

= very well suited = suitable = limited suitability

HPC machine reamers

for series applications on modern machining centres

Application:

For serial production of fi t tolerances on modern CNC machines with robust clamping of tool and workpiece.

advantage:

innovative cutting geometry ensures very high dimensional stability and process reliability at very high cutting parameters

high-quality cemented carbide cutting material and coating make for a very long service life

innovative coating technology ensures an increased service life

internal cooling ensures optimal transport of chips

wide range with specialists for the most common materials

diameter and tolerance can be ordered individually with short delivery times

HPC reamers available as H7, 1/100 mm and special reamers

all geometries available for through hole and blind hole machining

H7 0,001 0,00X VHM

Cutting P 1000 P 1300

H

Ø material N/mm N/mm 2 M N K S 65HRC

2

High-performance reamer,

11781050-286 solid carbide, TiALN With cast 3.97-20.0 mm VHM

steel geometry for use up to

1300 N/mm 2

High-performance reamer,

11781350-586 solid carbide TiALN With cast 3.97-20.0 mm VHM

steel geometry for use up to

1300 N/mm 2

High-performance reamer, solid

carbide TiALN (fi t tolerance and

11781604-628 diameter can be selected) With 3.80-20.20 mm VHM

cast steel geometry for use up

to 1300 N/mm 2

High-performance reamer, solid

carbide TiALN (fi t tolerance and

11781633-657 diameter can be selected) With 3.80-20.20 mm VHM

cast steel geometry for use up

to 1300 N/mm 2

High-performance reamer, solid

11783604-628 carbide TiALN (fi t tolerance and 3.80-20.20 mm VHM

diameter can be selected) for

use in stainless steels

High-performance reamer, solid

11783633-657 carbide TiALN (fi t tolerance and 3.80-20.20 mm VHM

diameter can be selected) for

use in stainless steels

High-performance reamer,

solid carbide, TiALN (fi t and

11784604-628 diameter may be selected) For 3.80-20.20 mm VHM

use in hardened steels up to

63 HRC

Solid carbide TiALCN high-per-

11734200-292 formance reamer for universal 3.97-20.0 mm VHM

use up to 1300N/mm 2

Solid carbide TiALCN high-per-

11737200-288 formance reamer for universal 3.97-20.0 mm VHM

use up to 1300N/mm 2

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 127

0160_EN_2018_KERN[21846869]-h.indd 161 12/17/2018 3:31:07 PM