Page 184 - Icon Ridge Presents ATORN

P. 184

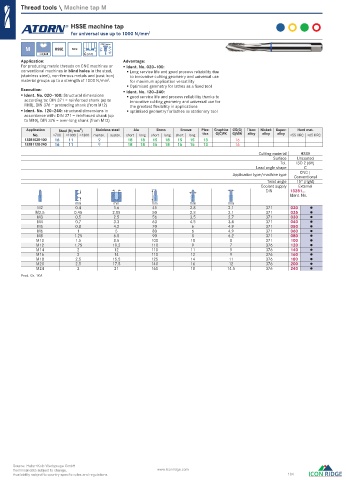

Thread tools \ Machine tap M

HSSE machine tap

for universal use up to 1000 N/mm 2

CNC/conv.

M HSSE

2,5xd C (2-3)

Application: Advantage:

For producing metric threads on CNC machines or Ident. No. 020–100:

conventional machines in blind holes in the steel, Long service life and good process reliability due

(stainless steel), non-ferrous metals and (cast iron) to innovative cutting geometry and universal use

material groups up to a strength of 1000 N/mm . 2 for maximum application versatility

Optimised geometry for lathes as a fi xed tool

Execution: Ident. No. 120–240:

Ident. No. 020–100: Structural dimensions good service life and process reliability thanks to

according to: DIN 371 = reinforced shank (up to innovative cutting geometry and universal use for

M10), DIN 376 = protruding shank (from M12) the greatest fl exibility in applications

Ident. No. 120–240: structural dimensions in optimised geometry for lathes as stationary tool

accordance with: DIN 371 = reinforced shank (up

to M10), DIN 376 = over-long shank (from M12)

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13281020-100 16 11 9 18 18 15 18 15 15 13 16

13281120-240 16 11 9 18 18 15 18 15 15 13 16

Cutting material HSSE

Surface Uncoated

Tol. ISO 2 (6H)

Lead angle shape C

CNC |

Application type/machine type Conventional

Twist angle 15° (right)

Coolant supply External

DIN 13281...

Ident. No.

mm mm mm mm mm

M2 0.4 1.6 45 2.8 2.1 371 020

M2.5 0.45 2.05 50 2.8 2.1 371 025

M3 0.5 2.5 56 3.5 2.7 371 030

M4 0.7 3.3 63 4.5 3.4 371 040

M5 0.8 4.2 70 6 4.9 371 050

M6 1 5 80 6 4.9 371 060

M8 1.25 6.8 90 8 6.2 371 080

M10 1.5 8.5 100 10 8 371 100

M12 1.75 10.2 110 9 7 376 120

M14 2 12 110 11 9 376 140

M16 2 14 110 12 9 376 160

M18 2.5 15.5 125 14 11 376 180

M20 2.5 17.5 140 16 12 376 200

M24 3 21 160 18 14.5 376 240

Prod. Gr. 1KA

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 184

0219_EN_2018_KERN[21847020]-s.indd 220 12/17/2018 3:31:44 PM