Page 200 - Icon Ridge Presents ATORN

P. 200

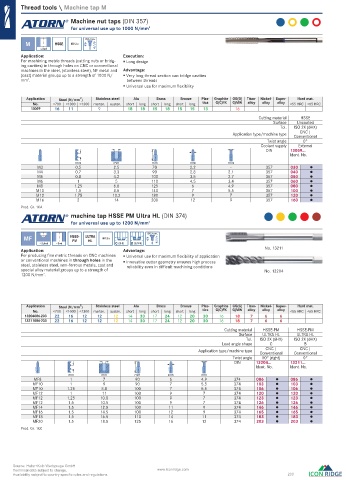

Thread tools \ Machine tap M

Machine nut taps ( DIN 357 )

for universal use up to 1000 N/mm 2

CNC/conv.

M HSSE ISO 2 x

3xd

Application: Execution:

For machining metric threads (cutting nuts or bridg- Long design

ing cavities) in through holes on CNC or conventional

machines in the steel, (stainless steel), NF metal and Advantage:

(cast) material groups up to a strength of 1000 N/ Very long thread section can bridge cavities

mm . 2 between threads

Universal use for maximum fl exibility

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13059 16 11 9 18 18 15 18 15 15 13 16

Cutting material HSSE

Surface Uncoated

Tol. ISO 2X (6HX)

CNC |

Application type/machine type Conventional

Twist angle 0°

Coolant supply External

DIN 13059...

Ident. No.

mm mm mm mm mm

M3 0.5 2.5 70 2.2 - 357 030

M4 0.7 3.3 90 2.8 2.1 357 040

M5 0.8 4.2 100 3.5 2.7 357 050

M6 1 5 110 4.5 3.4 357 060

M8 1.25 6.8 125 6 4.9 357 080

M10 1.5 8.5 140 7 5.5 357 100

M12 1.75 10.2 180 9 7 357 120

M16 2 14 200 12 9 357 160

Prod. Gr. 1KA

machine tap HSSE PM Ultra HL ( DIN 374 )

for universal use up to 1200 N/mm 2

CNC/conv.

MF HSSE- ULTRA ISO 2 x

HL

PM

2,5xd 3xd C (2-3) B (3,5-5)

Application: Advantage: No. 13211

For producing fi ne metric threads on CNC machines Universal use for maximum fl exibility of application

or conventional machines in through holes in the Innovative cutter geometry ensures high process

steel, stainless steel, non-ferrous metals, cast and reliability even in diffi cult machining conditions

special alloy material groups up to a strength of No. 13204

1200 N/mm . 2

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13204086-203 22 16 12 12 12 14 30 17 24 12 20 30 16 18 7 6 6

13211086-203 22 16 12 12 12 14 30 17 24 12 20 30 16 18 7 6 6

Cutting material HSSE-PM HSSE-PM

Surface ULTRA HL ULTRA HL

Tol. ISO 2X (6HX) ISO 2X (6HX)

Lead angle shape C B

CNC |

CNC |

Application type/machine type Conventional Conventional

Twist angle 50° (right) 0°

DIN 13204... 13211...

Ident. No. Ident. No.

mm mm mm mm mm

MF8 1 7 90 6 4.9 374 086 086

MF10 1 9 90 7 5.5 374 103 103

MF10 1.25 8.8 100 7 5.5 374 106 106

MF12 1 11 100 9 7 374 120 120

MF12 1.25 10.8 100 9 7 374 123 123

MF12 1.5 10.5 100 9 7 374 126 126

MF14 1.5 12.5 100 11 9 374 146 146

MF16 1.5 14.5 100 12 9 374 165 165

MF18 1.5 16.5 110 14 11 374 183 183

MF20 1.5 18.5 125 16 12 374 203 203

Prod. Gr. 1KC

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 200

0235_EN_2018_KERN[21847044]-o.indd 236 12/17/2018 3:32:11 PM