Page 243 - Icon Ridge Presents ATORN

P. 243

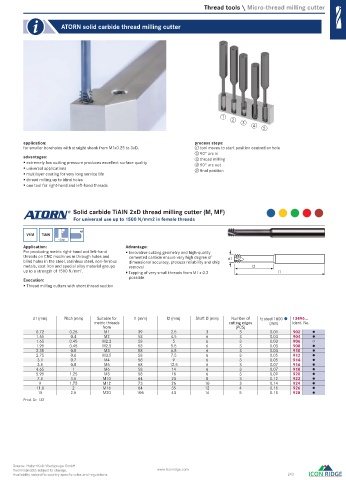

Thread tools \ Micro-thread milling cutter

ATORN solid carbide thread milling cutter

1

2

3

4

5

application: process steps:

for smaller boreholes with straight shank from M1x0.25 to 3xD. ① tool moves to start position centred on hole

② 90° arc in

advantages: ③ thread milling

extremely low cutting pressure produces excellent surface quality ④ 90° arc out

universal applications ⑤ fi nal position

multilayer coating for very long service life

thread milling up to blind holes

one tool for right-hand and le -hand threads

Solid carbide TiAlN 2xD thread milling cutter (M, MF)

For universal use up to 1500 N/mm2 in female threads

HA

VHM TiAlN

2xd

Application: Advantage:

For producing metric right-hand and le -hand Innovative cutting geometry and high-quality

threads on CNC machines in through holes and cemented carbide ensure very high degree of d1

blind holes in the steel, stainless steel, non-ferrous dimensional accuracy, process reliability and chip

metals, cast iron and special alloy material groups removal l2

up to a strength of 1500 N/mm . 2 Tapping of very small threads from M1 x 0.2 l1

Execution: possible

Thread milling cutters with short thread section

d1 (mm) Pitch (mm) Suitable for l1 (mm) l2 (mm) Sha Ø (mm) Number of fz steel 1000 13496...

metric threads cutting edges (mm) Ident. No.

from (PCS)

0.72 0.25 M1 39 2.5 3 3 0.01 902

1.55 0.4 M2 58 4.5 6 3 0.03 904

1.65 0.45 M2.2 58 5 6 3 0.03 906 ○

1.95 0.45 M2.5 58 5.5 6 3 0.03 908

2.35 0.5 M3 58 6.5 6 3 0.03 910

2.75 0.6 M3.5 58 7.5 6 3 0.05 912

3.1 0.7 M4 58 9 6 3 0.05 914

3.8 0.8 M5 58 12.5 6 3 0.07 916

4.65 1 M6 58 14 6 3 0.07 918

5.95 1.25 M8 58 18 6 3 0.09 920

7.8 1.5 M10 64 23 8 3 0.12 922

9 1.75 M12 73 26 10 3 0.14 924

11.8 2 M16 84 35 12 4 0.16 926

15 2.5 M20 105 43 16 5 0.18 928

Prod. Gr. 132

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 243

0276_EN_2018_KERN[21847355]-o.indd 279 12/17/2018 3:32:19 PM