Page 252 - Icon Ridge Presents ATORN

P. 252

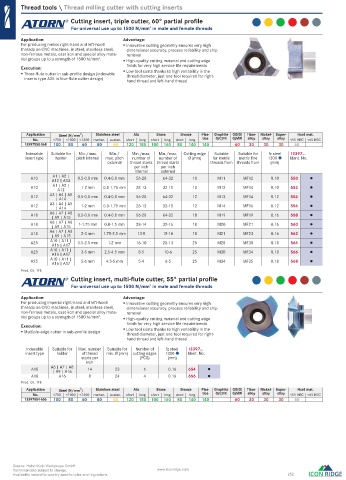

Thread tools \ Thread milling cutter with cutting inserts

Cutting insert, triple cutter, 60° partial profi le

For universal use up to 1500 N/mm in male and female threads

2

Application: Advantage:

For producing metric right-hand and le -hand Innovative cutting geometry ensures very high

threads on CNC machines, in steel, stainless steel, dimensional accuracy, process reliability and chip

non-ferrous metals, cast iron and special alloy mate- removal

rial groups up to a strength of 1500 N/mm . 2 High-quality cutting material and cutting edge

fi nish for very high service life requirements

Execution: Low tool costs thanks to high variability in the

Three-fl ute cutter in sub-profi le design (indexable thread diameter, just one tool required for right-

inserts type A25 in four-fl ute cutter design) hand thread and le -hand thread

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13397550-568 100 80 60 80 60 120 180 100 160 80 140 140 60 30 30 30 60

Indexable Suitable for Min./max. Min./ Min./max. Min./max. Cutting edge Suitable Suitable for fz steel 13397...

insert type holder pitch internal max. pitch number of number of Ø (mm) for metric metric fi ne 1300 Ident. No.

external thread starts thread starts threads from threads from (mm)

per inch per inch

internal external

A1 | A2 |

A10 A12 | A13 0.5-0.8 mm 0.4-0.8 mm 56-28 64-32 10 M11 MF12 0.10 550

A10 A1 | A2 | 1-2 mm 0.8-1.75 mm 28-13 32-15 10 M12 MF14 0.10 552

A12

A12 A3 | A4 | A5 0.5-0.8 mm 0.4-0.8 mm 56-28 64-32 12 M13 MF14 0.12 554

| A14

A12 A3 | A4 | A5 1-2 mm 0.8-1.75 mm 28-13 32-15 12 M14 MF16 0.12 556

| A14

A18 A6 | A7 | A8 0.5-0.8 mm 0.4-0.8 mm 56-28 64-32 18 M19 MF19 0.16 558

| A9 | A15

A18 A6 | A7 | A8 1-1.75 mm 0.8-1.5 mm 28-14 32-16 18 M20 MF21 0.16 560

| A9 | A15

A18 A6 | A7 | A8 2-3 mm 1.75-2.5 mm 13-8 15-10 18 M21 MF23 0.16 562

| A9 | A15

A25 A10 | A11 | 1.5-2.5 mm 1-2 mm 16-10 28-13 25 M28 MF30 0.18 564

A16 | A17

A25 A10 | A11 | 3-5 mm 2.5-4.5 mm 8-5 10-6 25 M30 MF34 0.18 566

A16 | A17

A25 A10 | A11 | 5-6 mm 4.5-5 mm 5-4 6-5 25 M34 MF35 0.18 568

A16 | A17

Prod. Gr. 1FE

Cutting insert, multi-fl ute cutter, 55° partial profi le

For universal use up to 1500 N/mm in male and female threads

2

Application: Advantage:

For producing imperial right-hand and le -hand Innovative cutting geometry ensures very high

threads on CNC machines, in steel, stainless steel, dimensional accuracy, process reliability and chip

non-ferrous metals, cast iron and special alloy mate- removal

rial groups up to a strength of 1500 N/mm . 2 High-quality cutting material and cutting edge

Execution: fi nish for very high service life requirements

Multiple-edge cutter in sub-profi le design Low tool costs thanks to high variability in the

thread diameter, just one tool required for right-

hand thread and le -hand thread

Indexable Suitable for Max. number Suitable for Number of fz steel 13397...

insert type holder of thread min. Ø (mm) cutting edges 1300 Ident. No.

starts per (PCS) (mm)

inch

A18 A6 | A7 | A8 14 23 6 0.16 654

| A9 | A16

A18 A16 8 24 4 0.16 656

Prod. Gr. 1FE

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13397654-656 100 80 60 80 60 120 180 100 160 80 140 140 60 30 30 30 60

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 252

0288_EN_2018_KERN[21847426]-l.indd 288 12/17/2018 3:32:20 PM