Page 373 - Icon Ridge Presents ATORN

P. 373

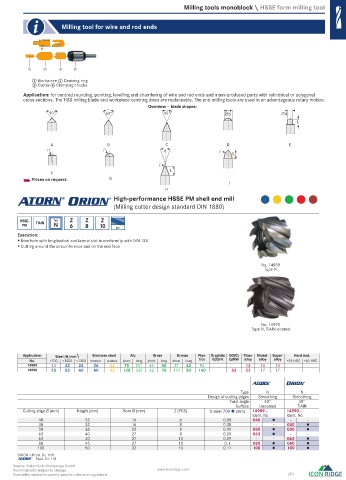

Milling tools monoblock \ HSSE form milling tool

Milling tool for wire and rod ends

1 2 3 4

1 Workpiece 2 Centring ring

3 Cutter 4 Clamping chucks

Application: for centred rounding, pointing, levelling and chamfering of wire and rod ends and mass-produced parts with cylindrical or polygonal

cross-sections. The HSS milling blade and workpiece centring discs are replaceable. The end-milling tools are used in an advantageous rotary motion.

Overview — blade shapes:

90° 60° 45° d d

L

A B C D E

r r a r L

r

F L

h Prices on request. G

J

H

High-performance HSSE PM shell end mill

( Milling cutter design standard DIN 1880 )

HSSE- TiAlN Typ Z Z Z

PM N 6 8 10

Execution:

Bore hole with longitudinal and lateral slot in conformity with DIN 138

Cutting around the circumference and on the end face

No. 14989

Type N

No. 14990

Type N, TiAlN-coated

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

14989 44 32 24 26 24 78 201 66 50 37 42 84 13 10 10

14990 73 53 40 40 43 130 335 62 70 110 83 140 63 22 17 17

Type N N

Design of cutting edges Smoothing Smoothing

Twist angle 40° 40°

Surface Uncoated TiAlN

Cutting edge Ø (mm) Height (mm) Bore Ø (mm) Z (PCS) fz steel 700 (mm) 14989... 14990...

Ident. No. Ident. No.

40 32 16 6 0.08 040 - -

40 32 16 8 0.08 - - 040

50 36 22 8 0.09 050 050

63 40 27 8 0.09 063 - -

63 40 27 10 0.09 - - 063

80 45 27 10 0.1 080 080

100 50 32 10 0.11 100 100

ORION = Prod. Gr. 1HH

a = Prod. Gr. 118

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 373

0443_EN_2018_KERN[21847712]-h.indd 443 12/17/2018 3:32:47 PM