Page 463 - Icon Ridge Presents ATORN

P. 463

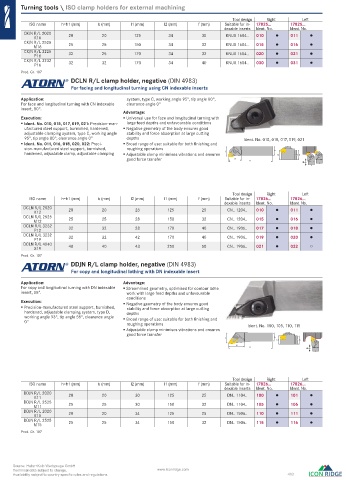

Turning tools \ ISO clamp holders for external machining

Tool design Right Le

ISO name h=h1 (mm) b (mm) l1 (mm) l2 (mm) f (mm) Suitable for in- 17825... 17825...

dexable inserts Ident. No. Ident. No.

CKJN R/L 2020 20 20 125 34 30 KNUX 1604.. 010 011

K16

CKJN R/L 2525 25 25 150 34 32 KNUX 1604.. 015 016

M16

CKJN R/L 3225 32 25 170 34 32 KNUX 1604.. 020 021

P16

CKJN R/L 3232 32 32 170 34 40 KNUX 1604.. 030 031

P16

Prod. Gr. 107

DCLN R/L clamp holder, negative ( DIN 4983 )

For facing and longitudinal turning using CN indexable inserts

Application: system, type C, working angle 95°, tip angle 80°,

For face and longitudinal turning with CN indexable clearance angle 0°

insert, 80°.

Advantage:

Execution: Universal use for face and longitudinal turning with

Ident. No. 010, 015, 017, 019, 021: Precision-man- large feed depths and unfavourable conditions

ufactured steel support, burnished, hardened, Negative geometry of the body ensures good

adjustable clamping system, type C, working angle stability and force absorption at large cutting

95°, tip angle 80°, clearance angle 0° depths Ident. No. 010, 015, 017, 019, 021

Ident. No. 011, 016, 018, 020, 022: Preci- Broad range of use: suitable for both fi nishing and

sion-manufactured steel support, burnished, roughing operations b

hardened, adjustable clamp, adjustable clamping Adjustable clamp minimises vibrations and ensures f h1 h

good force transfer l2 l1

Tool design Right Le

ISO name h=h1 (mm) b (mm) l2 (mm) l1 (mm) f (mm) Suitable for in- 17826... 17826...

dexable inserts Ident. No. Ident. No.

DCLN R/L 2020 010 011

K12 20 20 28 125 25 CN.. 1204..

DCLN R/L 2525 25 25 28 150 32 CN.. 1204.. 015 016

M12

DCLN R/L 3232 32 32 28 170 40 CN.. 1906.. 017 018

P12

DCLN R/L 3232 32 32 42 170 40 CN.. 1906.. 019 020

P19

DCLN R/L 4040 40 40 43 250 50 CN.. 1906.. 021 022 ○

S19

Prod. Gr. 107

DDJN R/L clamp holder, negative ( DIN 4983 )

For copy and longitudinal lathing with DN indexable insert

Application: Advantage:

For copy and longitudinal turning with DN indexable Streamlined geometry, optimised for contour lathe

insert, 55°. work with large feed depths and unfavourable

conditions

Execution: Negative geometry of the body ensures good

Precision-manufactured steel support, burnished, stability and force absorption at large cutting

hardened, adjustable clamping system, type D, depths

working angle 93°, tip angle 55°, clearance angle Broad range of use: suitable for both fi nishing and

0° roughing operations Ident. No. 100, 105, 110, 115

Adjustable clamp minimises vibrations and ensures

good force transfer

f b

h1 h

l2

l1

Tool design Right Le

ISO name h=h1 (mm) b (mm) l2 (mm) l1 (mm) f (mm) Suitable for in- 17826... 17826...

dexable inserts Ident. No. Ident. No.

DDJN R/L 2020 20 20 30 125 25 DN.. 1104.. 100 101

K11

DDJN R/L 2525 25 25 30 150 32 DN.. 1104.. 105 106

M11

DDJN R/L 2020 20 20 34 125 25 DN.. 1506.. 110 111

K15

DDJN R/L 2525 25 25 34 150 32 DN.. 1506.. 115 116

M15

Prod. Gr. 107

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 463

0594_EN_2018_KERN[21847901]-k.indd 596 12/17/2018 3:33:32 PM