Page 488 - Icon Ridge Presents ATORN

P. 488

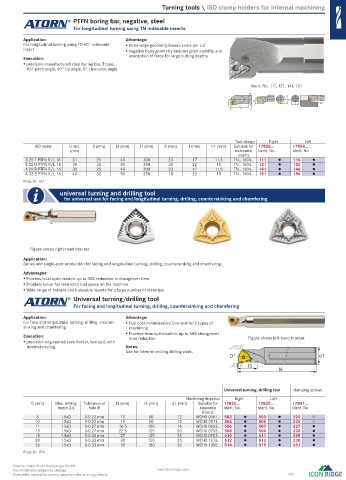

Turning tools \ ISO clamp holders for internal machining

PTFN boring bar, negative, steel

For longitudinal turning using TN indexable inserts

Application: Advantage:

For longitudinal turning using TN 60° indexable three-edge geometry lowers costs per cut

insert negative body geometry ensures good stability and

Execution: absorption of force for large cutting depths

precision-manufactured steel boring bar, T type,

90° pitch angle, 60° tip angle, 0° clearance angle

Ident. No. 111, 121, 141, 151

d

ØDmin.

h1

f

h

l2

l1

Tool design Right Le�

ISO name D min. d (mm) l2 (mm) l1 (mm) h (mm) f (mm) h1 (mm) Suitable for 17858... 17858...

(mm) indexable Ident. No. Ident. No.

inserts

S 25 T PTFN R/L 16 31 25 40 300 23 17 11.5 TN.. 1604.. 111 ● 116 ●

S 32 U PTFN R/L 16 39 32 50 350 30 22 15 TN.. 1604.. 121 ● 126 ●

A 25 R PTFN R/L 16 32 25 40 200 23 17 11.5 TN.. 1604.. 141 ● 146 ●

A 32 S PTFN R/L 16 40 32 50 250 15 22 15 TN.. 1604.. 151 ● 156 ●

Prod. Gr. 107

universal turning and drilling tool

for universal use for facing and longitudinal turning, drilling, countersinking and chamfering

Figure shows right-hand bracket

Application:

Series and single-part production for facing and longitudinal turning, drilling, countersinking and chamfering.

Advantages:

Process/cost optimisation: up to 30% reduction in changeover time

Problem solver for restricted tool space on the machine

Wide range of holders and indexable inserts for a large number of materials

Universal turning/drilling tool

For facing and longitudinal turning, drilling, countersinking and chamfering

Application: Advantage:

For face and longitudinal turning, drilling, counter- Tool cost minimisation: One tool for 5 types of

sinking and chamfering. machining

Execution: Process-time optimisation: up to 30% changeover Figure shows le� -hand bracket

time reduction

precision-engineered steel holder, bronzed, with

internal cooling Notes:

Use for internal cooling drilling work.

D* d1

l3

l4

Universal turning/drilling tool clamping screws

Machining direction Right Le�

D (mm) Max. drilling Tolerance of l3 (mm) l4 (mm) d1 (mm) Suitable for 17820... 17820... 17841...

depth (D) hole Ø indexable Ident. No. Ident. No. Ident. No.

inserts

8 1.5xD 0-0.22 mm 12 80 12 WCHX 0401.. 502 ● 503 ● 225 ○

10 1.5xD 0-0.22 mm 15 90 12 WCHX 05T1.. 504 ● 505 ● 226 ○

11 1.5xD 0-0.27 mm 16.5 100 16 WCHX 0602.. 506 ● 507 ● 227 ●

15 1.5xD 0-0.27 mm 22.5 125 20 WCHX 0703.. 508 ● 509 ● 228 ●

18 1.5xD 0-0.33 mm 27 135 25 WCHX 0903.. 510 ● 511 ● 229 ●

20 1.5xD 0-0.33 mm 30 150 25 WCHX 10T3.. 512 ● 513 ● 230 ●

26 1.5xD 0-0.33 mm 39 180 32 WCHX 1305.. 514 ● 515 ● 231 ●

Prod. Gr. 1FN

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 488

0621_EN_2018_KERN[21847940]-j.indd 621 12/17/2018 3:33:11 PM