Page 52 - Icon Ridge Presents ATORN

P. 52

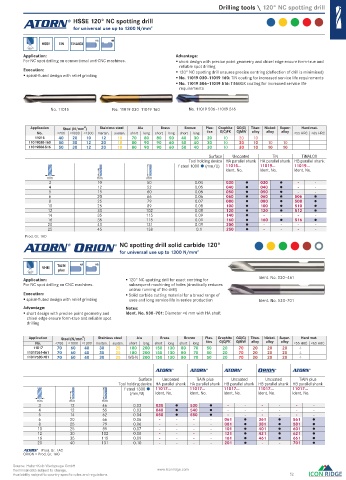

Drilling tools \ 120° NC spotting drill

HSSE 120° NC spotting drill

for universal use up to 1300 N/mm 2

HA HB

HSSE TiN TiNAlOX

120°

Application: Advantage:

For NC spot drilling on conventional and CNC machines. short design with precise point geometry and chisel edge ensure form-true and

reliable spot drilling

Execution: 120° NC spotting drill ensures precise centring (defl ection of drill is minimised)

spiral-fl uted design with relief grinding No. 11019 030–11019 160: TiN coating for increased service life requirements

No. 11019 506–11019 516: TiNAlOX coating for increased service life

requirements

No. 11015 No. 11019 030–11019 160 No. 11019 506–11019 516

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11015 40 20 10 12 10 70 80 80 50 40 30 20 10 20 10

11019030-160 50 30 12 20 18 80 90 90 60 50 40 30 10 30 10 10 10

11019506-516 50 30 12 20 18 80 90 90 60 50 40 30 10 30 10 10 10

Surface Uncoated TiN TiNALOX

Tool holding device HA parallel shank HA parallel shank HB parallel shank

f steel 1000 (mm/U) 11015... 11019... 11019...

Ident. No. Ident. No. Ident. No.

mm mm mm

3 10 50 0.04 030 030 - -

4 12 52 0.05 040 040 - -

5 15 60 0.05 050 050 - -

6 20 66 0.06 060 060 506

8 25 79 0.07 080 080 508

10 25 89 0.08 100 100 510

12 30 102 0.08 120 120 512

14 35 115 0.09 140 - - - -

16 35 115 0.09 160 160 516

20 40 131 0.09 200 - - - -

25 45 138 0.1 250 - - - -

Prod. Gr. 1AD

NC spotting drill solid carbide 120°

for universal use up to 1300 N/mm 2

TiAlN HA HB

VHM

120° plus

Application: 120° NC spotting drill for exact centring for Ident. No. 030–461

For NC spot drilling on CNC machines. subsequent machining of holes (drastically reduces

untrue running of the drill)

Execution: Solid carbide cutting material for a broad range of

spiral-fl uted design with relief grinding uses and long service life in series production Ident. No. 530–701

Advantage: Notes:

short design with precise point geometry and Ident. No. 530–701: Diameter <6 mm with HA sha

chisel edge ensure form-true and reliable spot

drilling

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11017 70 60 40 30 25 180 200 150 130 80 70 50 20 70 20 20 20 4

11017361-461 70 60 40 30 25 180 200 150 130 80 70 50 20 70 20 20 20 4

11017530-701 70 60 40 30 25 WS-N 200 150 130 80 70 50 20 70 20 20 20 4

Surface Uncoated TiAlN plus Uncoated Uncoated TiAlN plus

Tool holding device HA parallel shank HA parallel shank HB parallel shank HB parallel shank HB parallel shank

f steel 1300 11017... 11017... 11017... 11017... 11017...

(mm/U) Ident. No. Ident. No. Ident. No. Ident. No. Ident. No.

mm mm mm

3 12 46 0.03 030 530 - - - - - -

4 12 55 0.03 040 540 - - - - - -

5 14 62 0.04 050 550 - - - - - -

6 20 66 0.06 - - - - 061 361 561

8 25 79 0.06 - - - - 081 381 581

10 25 89 0.07 - - - - 101 401 601

12 30 102 0.08 - - - - 121 421 621

16 35 115 0.09 - - - - 161 461 661

20 40 131 0.10 - - - - 201 - - 701

a = Prod. Gr. 1AC

ORION = Prod. Gr. 1AO

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 52

0061_EN_2018_KERN[21841759]-m.indd 61 12/17/2018 3:31:04 PM