Page 535 - Icon Ridge Presents ATORN

P. 535

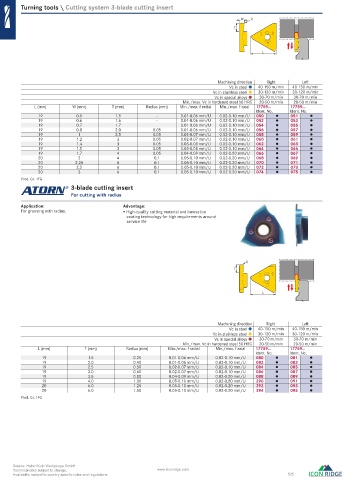

Turning tools \ Cutting system 3-blade cutting insert

W R

T

L

Machining direction Right Le

Vc in steel 40-150 m/min 40-150 m/min

Vc in stainless steel 30-120 m/min 30-120 m/min

Vc in special alloys 30-70 m/min 30-70 m/min

Min./max. Vc in hardened steel 50 HRC 20-50 m/min 20-50 m/min

L (mm) W (mm) T (mm) Radius (mm) Min./max. f radial Min./max. f axial 17759... 17759...

Ident. No. Ident. No.

19 0.5 1.5 - 0.01-0.06 mm/U 0.02-0.10 mm/U 050 051

19 0.6 1.6 - 0.01-0.06 mm/U 0.02-0.10 mm/U 052 053

19 0.7 1.7 - 0.01-0.06 mm/U 0.02-0.10 mm/U 054 055

19 0.8 2.0 0.05 0.01-0.06 mm/U 0.02-0.10 mm/U 056 057

19 1 2.5 0.05 0.02-0.07 mm/U 0.02-0.10 mm/U 058 059

19 1.2 3 0.05 0.02-0.07 mm/U 0.02-0.10 mm/U 060 061

19 1.4 3 0.05 0.03-0.08 mm/U 0.02-0.10 mm/U 062 063

19 1.5 3 0.05 0.03-0.08 mm/U 0.02-0.10 mm/U 064 065

19 1.7 4 0.05 0.04-0.09 mm/U 0.02-0.20 mm/U 066 067

20 2 4 0.1 0.05-0.10 mm/U 0.02-0.20 mm/U 068 069

20 2.25 5 0.1 0.05-0.10 mm/U 0.02-0.20 mm/U 070 071

20 2.5 6 0.1 0.05-0.10 mm/U 0.02-0.20 mm/U 072 073

20 3 6 0.1 0.05-0.10 mm/U 0.02-0.20 mm/U 074 075

Prod. Gr. 1FG

3-blade cutting insert

For cutting with radius

Application: Advantage:

For grooving with radius. High-quality cutting material and innovative

coating technology for high requirements around

service life

R

T

L

Machining direction Right Le

Vc in steel 40-150 m/min 40-150 m/min

Vc in stainless steel 30-120 m/min 30-120 m/min

Vc in special alloys 30-70 m/min 30-70 m/min

Min./max. Vc in hardened steel 50 HRC 20-50 m/min 20-50 m/min

L (mm) T (mm) Radius (mm) Min./max. f radial Min./max. f axial 17759... 17759...

Ident. No. Ident. No.

19 1.5 0.25 0.01-0.06 mm/U 0.02-0.10 mm/U 080 081

19 2.0 0.40 0.01-0.06 mm/U 0.02-0.10 mm/U 082 083

19 2.5 0.50 0.02-0.07 mm/U 0.02-0.10 mm/U 084 085

19 3.0 0.60 0.02-0.07 mm/U 0.02-0.10 mm/U 086 087

19 3.5 0.80 0.04-0.09 mm/U 0.02-0.20 mm/U 088 089

19 4.0 1.00 0.05-0.10 mm/U 0.02-0.20 mm/U 290 091

20 6.0 1.25 0.05-0.10 mm/U 0.02-0.20 mm/U 292 093

20 6.0 1.50 0.05-0.10 mm/U 0.02-0.20 mm/U 294 095

Prod. Gr. 1FG

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 535

0667_EN_2018_KERN[21848005]-i.indd 668 12/17/2018 3:33:43 PM