Page 89 - Icon Ridge Presents ATORN

P. 89

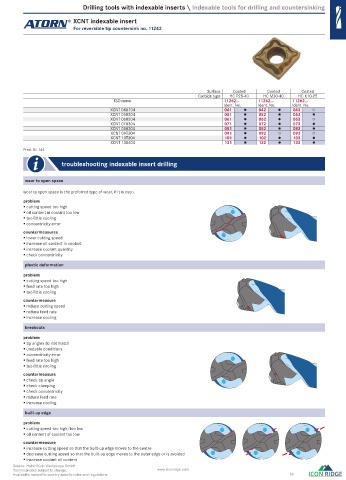

Drilling tools with indexable inserts \ Indexable tools for drilling and countersinking

XCNT indexable insert

For reversible tip countersink no. 11242

Surface Coated Coated Coated

Carbide type HC P25-40 HC M30-40 HC K10-25

ISO name 11262... 11262... 11262...

Ident. No. Ident. No. Ident. No.

XCNT 040104 041 042 043 ○

XCNT 050204 051 052 053

XCNT 060204 061 062 063 ○

XCNT 070304 071 072 073

XCNT 080304 081 082 083

XCNT 09T304 091 092 ○ 093 ○

XCNT 10T304 101 102 103

XCNT 130404 131 132 133

Prod. Gr. 144

troubleshooting indexable insert drilling

wear to open space

wear to open space is the preferred type of wear, if it is even.

problem

cutting speed too high

oil content in coolant too low

too little cooling

concentricity error

countermeasures

lower cutting speed

increase oil content in coolant

increase coolant quantity

check concentricity

plastic deformation

problem

cutting speed too high

feed rate too high

too little cooling

countermeasure

reduce cutting speed

reduce feed rate

increase cooling

breakouts

problem

tip angles do not match

unstable conditions

concentricity error

feed rate too high

too little cooling

countermeasure

check tip angle

check clamping

check concentricity

reduce feed rate

increase cooling

built-up edge

problem

cutting speed too high/too low

oil content of coolant too low

countermeasure

increase cutting speed so that the built-up edge moves to the centre

decrease cutting speed so that the built-up edge moves to the outer edge or is avoided

increase coolant oil content

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 89

0115_EN_2018_KERN[21841622]-n.indd 115 12/17/2018 3:31:03 PM