Page 100 - Icon Ridge Presents ATORN

P. 100

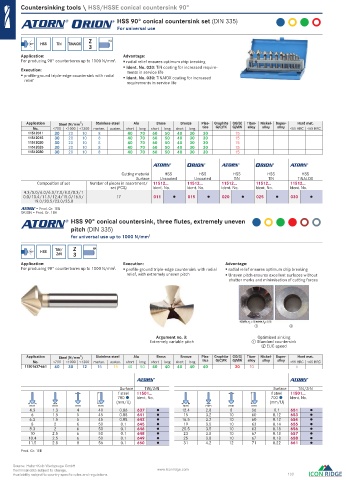

Countersinking tools \ HSS/HSSE conical countersink 90°

HSS 90° conical countersink set ( DIN 335 )

For universal use

Z HA

HSS TiN TiNAlOX

3

Application: Advantage:

For producing 90° counterbores up to 1000 N/mm . 2 radial relief ensures optimum chip breaking

Execution: Ident. No. 020: TiN coating for increased require-

ments in service life

profi le-ground triple-edge countersink with radial Ident. No. 030: TiNAlOX coating for increased

relief requirements in service life

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11512011 30 20 10 8 40 70 60 50 40 30 30 15

11512015 30 20 10 8 40 70 60 50 40 30 30 15

11512020 30 20 10 8 40 70 60 50 40 30 30 15

11512025 30 20 10 8 40 70 60 50 40 30 30 15

11512030 30 20 10 8 40 70 60 50 40 30 30 15

Cutting material HSS HSS HSS HSS HSS

Surface Uncoated Uncoated TiN TiN TiNALOX

Composition of set Number of pieces in assortment/ 11512... 11512... 11512... 11512... 11512...

set (PCS) Ident. No. Ident. No. Ident. No. Ident. No. Ident. No.

4.3/5.0/6.0/6.3/7.0/8.0/8.3/1

0.0/10.4/11.5/12.4/15.0/16.5/ 17 011 015 020 025 030

19.0/20.5/23.0/25.0

a = Prod. Gr. 1EB

ORION = Prod. Gr. 1EH

HSS 90° conical countersink, three fl utes, extremely uneven

pitch ( DIN 335 )

for universal use up to 1000 N/mm 2

HSS TiN/ Z HA

ZrN 3

Application: Execution: Advantage:

For producing 90° counterbores up to 1000 N/mm . 2 profi le-ground triple-edge countersink with radial radial relief ensures optimum chip breaking

relief, with extremely uneven pitch Uneven pitch ensures excellent surfaces without

chatter marks and minimisation of cutting forces

1 2

Argument no. 3: Optimised sinking

Extremely variable pitch ① Standard countersink

② EUC speed

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11501637-661 40 30 12 15 15 40 50 40 40 40 40 40 20 10 6

Surface TiN/ZrN Surface TiN/ZrN

f steel 11501... f steel 11501...

700 Ident. No. 700 Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

4.3 1.3 4 40 0.06 637 12.4 2.8 8 56 0.1 651

6 1.5 5 45 0.08 641 15 3.2 10 60 0.12 653

6.3 1.5 5 45 0.08 642 16.5 3.2 10 60 0.12 654

8 2 6 50 0.1 645 19 3.5 10 63 0.14 655

8.3 2 6 50 0.1 646 20.5 3.5 10 63 0.18 656

10 2.5 6 50 0.1 648 23 3.8 10 67 0.18 657

10.4 2.5 6 50 0.1 649 25 3.8 10 67 0.18 658

11.5 2.8 8 56 0.1 650 31 4.2 12 71 0.22 661

Prod. Gr. 1EB

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 100

0126_EN_2018_KERN[21846802]-k.indd 126 12/17/2018 3:31:07 PM