Page 123 - Icon Ridge Presents ATORN

P. 123

Reaming tools \ Technical introduction – reaming

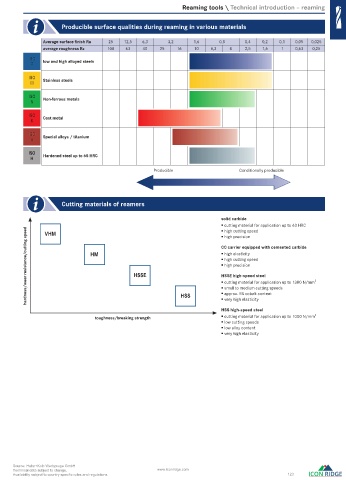

Producible surface qualities during reaming in various materials

Average surface fi nish Ra 25 12,5 6,3 3,2 1,6 0,8 0,4 0,2 0,1 0,05 0,025

average roughness Rz 100 63 40 25 16 10 6,3 4 2,5 1,6 1 0,63 0,25

ISO low and high alloyed steels

P

ISO Stainless steels

M

ISO Non-ferrous metals

N

ISO Cast metal

K

ISO Special alloys / titanium

S

ISO Hardened steel up to 65 HRC

H

Producible Conditionally producible

Cutting materials of reamers

solid carbide

cutting material for application up to 63 HRC

hardness/wear resistance/cutting speed HM HSSE CC carrier equipped with cemented carbide 2

high cutting speed

VHM

high precision

high elasticity

high cutting speed

high precision

HSSE high-speed steel

cutting material for application up to 1300 N/mm

small to medium cutting speeds

approx. 5% cobalt content

HSS

very high elasticity

HSS high-speed steel

toughness/breaking strength cutting material for application up to 1000 N/mm 2

low cutting speeds

low alloy content

very high elasticity

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 123

0156_EN_2018_KERN[21846859]-k.indd 157 12/17/2018 3:31:00 PM