Page 151 - Icon Ridge Presents ATORN

P. 151

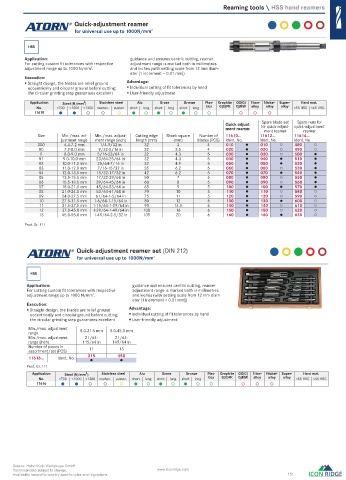

Reaming tools \ HSS hand reamers

Quick-adjustment reamer

for universal use up to 1000N/mm 2

HSS

Application: guidance and ensures centric cutting, reamer

For cutting custom fi t tolerances with respective adjustment range is marked both in millimetres

adjustment range up to 1000 N/mm . 2 and inches (with setting scale from 12 mm diam-

eter [1 increment = 0.01 mm])

Execution:

Straight design, the blades are relief ground Advantage:

eccentrically and circular ground before cutting; Individual cutting of fi t tolerances by hand

the circular grinding step guarantees excellent User-friendly adjustment

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11610

Quick-adjust- Spare blade set Spare nuts for

ment reamer for quick-adjust- quick-adjustment

reamer

ment reamer

Size Min./max. ad- Min./max. adjust- Cutting edge Shank square Number of 11610... 11612... 11614...

justment range ment range (inch) length (mm) (mm) blades (PCS) Ident. No. Ident. No. Ident. No.

000 6.4-7.2 mm 1/4-9/32 in 32 3 4 010 010 ○ 480 ○

00 7.2-8.0 mm 9/32-5/16 in 32 3.5 4 020 020 ○ 490 ○

0 8.0-9.0 mm 5/16-23/64 in 32 4.3 5 030 030 ○ 500

01 9.0-10.0 mm 23/64-25/64 in 32 4.3 5 040 040 510

02 10.0-11.0 mm 25/64-7/16 in 32 4.9 5 050 050 520

03 11.0-12.0 mm 7/16-15/32 in 35 6.2 5 060 060 ○ 530

04 12.0-13.5 mm 15/32-17/32 in 42 6.2 5 070 070 540

05 13.5-15.5 mm 17/32-39/64 in 50 7 5 080 080 ○ 550

06 15.5-18.0 mm 39/64-45/64 in 60 8 5 090 090 ○ 560

07 18.0-21.0 mm 45/64-53/64 in 65 9 5 100 100 570

08 21.0-24.0 mm 53/64-61/64 in 70 10 5 110 110 ○ 580 ○

09 24.0-27.5 mm 61/64-1-5/64 in 75 11 5 120 120 ○ 590 ○

10 27.5-31.5 mm 1-5/64-1-15/64 in 80 12 6 130 130 600 ○

11 31.5-37.5 mm 1-15/64-1-29/64 in 90 14.5 6 140 140 ○ 610 ○

12 37.0-45.0 mm 1-29/64-1-49/64 in 100 16 6 150 150 ○ 620 ○

13 45.0-55.0 mm 1-49/64-2-5/32 in 109 20 6 160 160 630 ○

Prod. Gr. 111

Quick-adjustment reamer set ( DIN 212 )

for universal use up to 1000N/mm 2

HSS

Application: guidance and ensures centric cutting, reamer

For cutting custom fi t tolerances with respective adjustment range is marked both in millimetres

adjustment range up to 1000 N/mm . 2 and inches (with setting scale from 12 mm diam-

eter [1 increment = 0.01 mm])

Execution:

Straight design, the blades are relief ground Advantage:

eccentrically and circular ground before cutting; Individual cutting of fi t tolerances by hand

the circular grinding step guarantees excellent User-friendly adjustment

Min./max. adjustment 8.0-31.5 mm 8.0-45.0 mm

range

Min./max. adjustment 21/64- 21/64-

range (inch) 115/64 in 149/64 in

Number of pieces in

assortment/set (PCS) 11 13

11616... Ident. No. 315 450

Prod. Gr. 111

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11616

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 151

0187_EN_2018_KERN[21846928]-l.indd 187 12/17/2018 3:31:39 PM