Page 248 - Icon Ridge Presents ATORN

P. 248

Thread tools \ Thread milling cutter with cutting inserts

thread milling system with indexable insert

for universal use

Multi-cutter attachments ensure high production rates and long service life

Innovative coating technology and cemented carbide mixtures for high service life and wide-ranging machining applications up to a hardness of 62 HRC

Very high surface quality of thread

Deep threads can be reliably produced

innovative coating technology and cemented carbide mixtures for high service life and wide-ranging

machining applications up to a hardness of 62 HRC

very high surface quality of thread

deep threads can be reliably produced

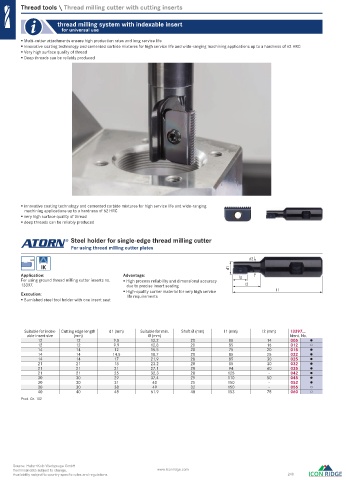

Steel holder for single-edge thread milling cutter

For using thread milling cutter plates

HB d2

IK d1

Application: Advantage: lp

For using ground thread milling cutter inserts no. High process reliability and dimensional accuracy

13397. due to precise insert seating l2

Execution: High-quality carrier material for very high service l1

life requirements

Burnished steel tool holder with one insert seat

Suitable for index- Cutting edge length d1 (mm) Suitable for min. Sha Ø (mm) l1 (mm) l2 (mm) 13397...

able insert size (mm) Ø (mm) Ident. No.

12 12 9.5 12.2 20 85 14 005

12 12 9.9 12.8 20 85 16 012 ○

14 14 12 15.5 20 75 20 015

14 14 14.5 18.7 20 85 25 022

14 14 17 21.9 20 85 30 025

21 21 18 23.2 20 85 30 032

21 21 21 27.1 20 94 40 035

21 21 25 32.3 20 125 - 042

30 30 29 37.4 25 110 50 045

30 30 31 40 25 150 - 052

30 30 38 49 32 150 - 055 ○

40 40 48 61.9 40 153 78 060 ○

Prod. Gr. 132

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 248

0284_EN_2018_KERN[21847420]-e.indd 284 12/17/2018 3:32:18 PM