Page 29 - Icon Ridge Presents ATORN

P. 29

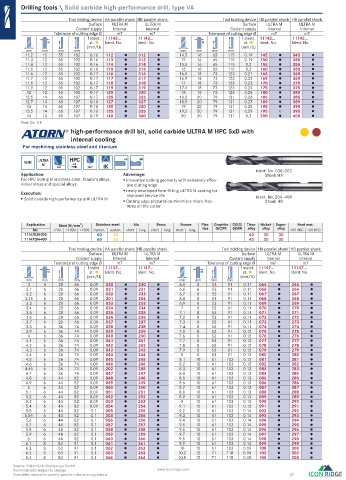

Drilling tools \ Solid carbide high-performance drill, type VA

Tool holding device HA parallel shank HB parallel shank Tool holding device HA parallel shank HB parallel shank

Surface ULTRA M ULTRA M Surface ULTRA M ULTRA M

Coolant supply Internal Internal Coolant supply Internal Internal

Tolerance of cutting edge Ø m7 m7 Tolerance of cutting edge Ø m7 m7

f steinl. 11142... 11142... f steinl. 11142... 11142...

h6 st. Ident. No. Ident. No. h6 st. Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

11.2 12 55 102 0.16 112 312 14.5 16 65 115 0.19 145 345

11.3 12 55 102 0.16 113 313 15 16 65 115 0.19 150 350

11.4 12 55 102 0.16 114 314 15.5 16 65 115 0.2 155 355

11.5 12 55 102 0.16 115 315 16 16 65 115 0.2 160 360

11.6 12 55 102 0.17 116 316 16.5 18 73 123 0.21 165 365

11.7 12 55 102 0.17 117 317 16.9 18 73 123 0.22 169 369

11.8 12 55 102 0.17 118 318 17 18 73 123 0.23 170 370

11.9 12 55 102 0.17 119 319 17.5 18 73 123 0.24 175 375

12 12 55 102 0.17 120 320 18 18 73 123 0.25 180 380

12.5 14 60 107 0.17 125 325 18.5 20 79 131 0.26 185 385

12.7 14 60 107 0.18 127 327 18.9 20 79 131 0.27 189 389

13 14 60 107 0.18 130 330 19 20 79 131 0.28 190 390

13.5 14 60 107 0.18 135 335 19.5 20 79 131 0.29 195 ○ 395

14 14 60 107 0.19 140 340 20 20 79 131 0.3 200 400

Prod. Gr. 113

high-performance drill bit, solid carbide ULTRA M HPC 5xD with

internal cooling

For machining stainless steel and titanium

ULTRA HPC HA HB

VHM

M VA IK

5xD 140° Ident. No. 030–203

Application: Advantage: Shank HA

For HPC boring in stainless steel, titanium alloys, innovative cutting geometry with extremely eff ec-

nickel alloys and special alloys. tive cutting edge

Execution: newly developed form-fi tting ULTRA M coating for

improved service life

Solid carbide high-performance drill ULTRA M Cutting edge preparation minimises micro-frac- Ident. No. 204–400

Shank HB

tures on the cutter

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11147030-203 60 55 40 30 30

11147204-400 60 55 40 30 30

Tool holding device HA parallel shank HB parallel shank Tool holding device HA parallel shank HB parallel shank

Surface ULTRA M ULTRA M Surface ULTRA M ULTRA M

Coolant supply Internal Internal Coolant supply Internal Internal

Tolerance of cutting edge Ø m7 m7 Tolerance of cutting edge Ø m7 m7

f steinl. 11147... 11147... f steinl. 11147... 11147...

h6 st. Ident. No. Ident. No. h6 st. Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

3 6 28 66 0.09 030 230 6.5 8 53 91 0.11 065 265

3.1 6 28 66 0.09 031 231 6.6 8 53 91 0.11 066 266

3.2 6 28 66 0.09 032 232 6.7 8 53 91 0.11 067 267

3.25 6 28 66 0.09 201 204 6.8 8 53 91 0.11 068 268

3.3 6 28 66 0.09 033 233 6.9 8 53 91 0.11 069 269

3.4 6 28 66 0.09 034 234 7 8 53 91 0.11 070 270

3.5 6 28 66 0.09 035 235 7.1 8 53 91 0.11 071 271

3.6 6 28 66 0.09 036 236 7.2 8 53 91 0.11 072 272

3.7 6 28 66 0.09 037 237 7.3 8 53 91 0.11 073 273

3.8 6 36 74 0.09 038 238 7.4 8 53 91 0.11 074 274

3.9 6 36 74 0.09 039 239 7.5 8 53 91 0.12 075 275

4 6 36 74 0.09 040 240 7.6 8 53 91 0.12 076 276

4.1 6 36 74 0.09 041 241 7.7 8 53 91 0.12 077 277

4.2 6 36 74 0.09 042 242 7.8 8 53 91 0.12 078 278

4.3 6 36 74 0.09 043 243 7.9 8 53 91 0.12 079 279

4.4 6 36 74 0.09 044 244 8 8 53 91 0.12 080 280

4.5 6 36 74 0.09 045 245 8.1 10 61 103 0.12 081 281

4.6 6 36 74 0.09 046 246 8.2 10 61 103 0.12 082 282

4.65 6 36 74 0.09 202 205 8.3 10 61 103 0.12 083 283

4.7 6 36 74 0.09 047 247 8.4 10 61 103 0.13 084 284

4.8 6 44 82 0.09 048 248 8.5 10 61 103 0.13 085 285

4.9 6 44 82 0.09 049 249 8.6 10 61 103 0.13 086 286

5 6 44 82 0.09 050 250 8.7 10 61 103 0.13 087 287

5.1 6 44 82 0.09 051 251 8.8 10 61 103 0.13 088 288

5.2 6 44 82 0.09 052 252 8.9 10 61 103 0.13 089 289

5.3 6 44 82 0.09 053 253 9 10 61 103 0.13 090 290

5.4 6 44 82 0.09 054 254 9.1 10 61 103 0.13 091 291

5.5 6 44 82 0.1 055 255 9.2 10 61 103 0.14 092 292

5.55 6 44 82 0.1 203 206 9.3 10 61 103 0.14 093 293

5.6 6 44 82 0.1 056 256 9.4 10 61 103 0.14 094 294

5.7 6 44 82 0.1 057 257 9.5 10 61 103 0.14 095 295

5.8 6 44 82 0.1 058 258 9.6 10 61 103 0.14 096 296

5.9 6 44 82 0.1 059 259 9.7 10 61 103 0.14 097 297

6 6 44 82 0.1 060 260 9.8 10 61 103 0.14 098 298

6.1 8 53 91 0.1 061 261 9.9 10 61 103 0.14 099 299

6.2 8 53 91 0.1 062 262 10 10 61 103 0.15 100 300

6.3 8 53 91 0.1 063 263 10.2 12 71 118 0.15 102 302

6.4 8 53 91 0.1 064 264 10.5 12 71 118 0.15 105 305

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 29

0037_EN_2018_KERN[21841696]-e.indd 38 12/17/2018 3:31:08 PM