Page 58 - Icon Ridge Presents ATORN

P. 58

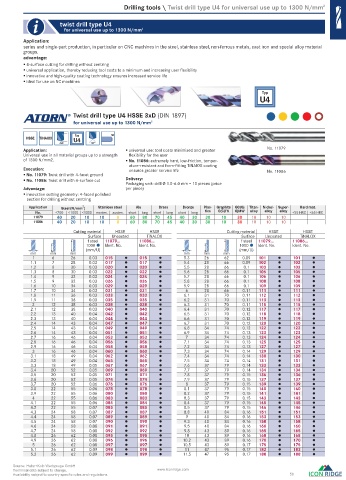

Drilling tools \ Twist drill type U4 for universal use up to 1300 N/mm 2

twist drill type U4

for universal use up to 1300 N/mm 2

Application:

series and single-part production, in particular on CNC machines in the steel, stainless steel, non-ferrous metals, cast iron and special alloy material

groups.

advantage:

4-surface cutting for drilling without centring

universal application, thereby reducing tool costs to a minimum and increasing user fl exibility

innovative and high-quality coating technology ensures increased service life

ideal for use on NC machines

Typ

U4

Twist drill type U4 HSSE 3xD ( DIN 1897 )

for universal use up to 1300 N/mm 2

Typ HA

HSSE TiNAlOX U4

3xD 118°

Application: universal use: tool costs minimised and greater No. 11079

Universal use in all material groups up to a strength fl exibility for the user

of 1300 N/mm2. No. 11086: extremely hard, low-friction, temper-

ature-resistant and form-fi tting TiNAlOX coating

Execution: ensures greater service life No. 11086

No. 11079: Twist drill with 4-facet ground

No. 11086: Twist drill with 4-surface cut Delivery:

Packaging unit: drill Ø 1.0-6.0 mm = 10 pieces (price

Advantage: per piece)

innovative cutting geometry: 4-faced polished

section for drilling without centring

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11079 40 20 10 10 8 60 80 70 45 40 30 30 10 30 10 10 10

11086 40 20 10 10 8 60 80 70 45 40 30 30 10 30 10 10 10

Cutting material HSSE HSSE Cutting material HSSE HSSE

Surface Uncoated TiNALOX Surface Uncoated TiNALOX

f steel 11079... 11086... f steel 11079... 11086...

1000 Ident. No. Ident. No. 1000 Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm

1 6 26 0.03 015 015 5.3 26 62 0.09 101 101

1.1 7 28 0.03 017 017 5.4 28 66 0.09 102 102

1.2 8 30 0.03 020 020 5.5 28 66 0.1 103 103

1.3 8 30 0.03 022 022 5.6 28 66 0.1 105 105

1.4 9 32 0.03 024 024 5.7 28 66 0.1 106 106

1.5 9 32 0.03 026 026 5.8 28 66 0.1 108 108

1.6 10 34 0.03 029 029 5.9 28 66 0.1 109 109

1.7 10 34 0.03 031 031 6 28 66 0.11 111 111

1.8 11 36 0.03 033 033 6.1 31 70 0.11 112 112

1.9 11 36 0.03 035 035 6.2 31 70 0.11 113 113

2 12 38 0.03 038 038 6.3 31 70 0.11 115 115

2.1 12 38 0.03 040 040 6.4 31 70 0.12 117 117

2.2 13 40 0.04 042 042 6.5 31 70 0.12 118 118

2.3 13 40 0.04 044 044 6.6 31 70 0.12 119 119

2.4 14 43 0.04 047 047 6.7 31 70 0.12 120 120

2.5 14 43 0.04 049 049 6.8 34 74 0.12 122 122

2.6 14 43 0.04 051 051 6.9 34 74 0.13 123 123

2.7 16 46 0.04 053 053 7 34 74 0.13 124 124

2.8 16 46 0.04 056 056 7.1 34 74 0.13 125 125

2.9 16 46 0.04 058 058 7.2 34 74 0.13 127 127

3 16 46 0.04 060 060 7.3 34 74 0.14 129 129

3.1 18 49 0.04 062 062 7.4 34 74 0.14 130 130

3.2 18 49 0.04 065 065 7.5 34 74 0.14 131 131

3.3 18 49 0.05 067 067 7.6 37 79 0.14 133 133

3.4 20 52 0.05 069 069 7.7 37 79 0.14 134 134

3.5 20 52 0.05 071 071 7.8 37 79 0.15 136 136

3.6 20 52 0.05 074 074 7.9 37 79 0.15 137 137

3.7 20 52 0.06 076 076 8 37 79 0.15 139 139

3.8 22 55 0.06 078 078 8.1 37 79 0.15 140 140

3.9 22 55 0.06 080 080 8.2 37 79 0.15 141 141

4 22 55 0.06 083 083 8.3 37 79 0.15 143 143

4.1 22 55 0.06 084 084 8.4 37 79 0.15 145 145

4.2 22 55 0.07 085 085 8.5 37 79 0.15 146 146

4.3 24 58 0.07 087 087 8.8 40 84 0.16 151 151

4.4 24 58 0.07 089 089 9 40 84 0.16 153 153

4.5 24 58 0.07 090 090 9.3 40 84 0.16 158 158

4.6 24 58 0.08 091 091 9.5 40 84 0.16 160 160

4.7 24 58 0.08 092 092 9.8 43 89 0.16 165 165

4.8 26 62 0.08 095 095 10 43 89 0.16 168 168

4.9 26 62 0.08 096 096 10.2 43 89 0.16 170 170

5 26 62 0.08 097 097 10.5 43 89 0.17 175 175

5.1 26 62 0.09 098 098 11 47 95 0.17 182 182

5.2 26 62 0.09 099 099 11.5 47 95 0.17 188 188

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 58

0067_EN_2018_KERN[21841774]-n.indd 67 12/17/2018 3:31:24 PM