Page 40 - Icon Ridge Presents ORION

P. 40

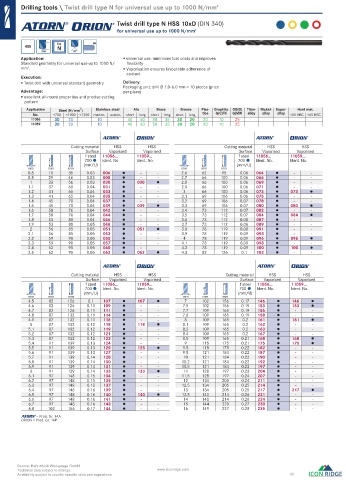

Drilling tools \ Twist drill type N for universal use up to 1000 N/mm 2

Twist drill type N HSS 10xD ( DIN 340 )

for universal use up to 1000 N/mm 2

Typ HA

HSS N

10xD 118°

Application: universal use: minimises tool costs and improves

Standard geometry for universal use up to 1000 N/ fl exibility

mm . 2 Vaporisation ensures favourable adherence of

coolant

Execution:

Twist drill with universal standard geometry Delivery:

Packaging unit: drill Ø 1.0-6.0 mm = 10 pieces (price

Advantage: per piece)

excellent all-round properties and precise cutting

pattern

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11056 30 20 10 40 60 50 35 30 20 20 10 25

11059 30 20 10 40 60 50 35 30 20 20 10 25

Cutting material HSS HSS Cutting material HSS HSS

Surface Vaporised Vaporised Surface Vaporised Vaporised

f steel 11056... 11059... f steel 11056... 11059...

700 Ident. No. Ident. No. 700 Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm

0.6 15 35 0.03 006 - - 2.6 62 95 0.06 064 - -

0.8 29 46 0.03 008 - - 2.7 66 100 0.06 066 - -

1 33 56 0.03 030 030 2.8 66 100 0.06 069 - -

1.1 37 60 0.04 031 - - 2.9 66 100 0.06 071 - -

1.2 41 65 0.04 033 - - 3 66 100 0.06 073 073

1.3 41 65 0.04 035 - - 3.1 69 106 0.06 075 - -

1.4 45 70 0.04 037 - - 3.2 69 106 0.07 078 - -

1.5 45 70 0.04 039 039 3.3 69 106 0.07 080 080

1.6 50 76 0.04 042 - - 3.4 73 112 0.07 082 - -

1.7 50 76 0.04 044 - - 3.5 73 112 0.07 084 084

1.8 53 80 0.04 046 - - 3.6 73 112 0.08 087 - -

1.9 53 80 0.05 048 - - 3.7 73 112 0.08 089 - -

2 56 85 0.05 051 051 3.8 78 119 0.08 091 - -

2.1 56 85 0.05 053 - - 3.9 78 119 0.09 093 - -

2.2 59 90 0.05 055 - - 4 78 119 0.09 096 096

2.3 59 90 0.05 057 - - 4.1 78 119 0.09 098 - -

2.4 62 95 0.05 060 - - 4.2 78 119 0.09 100 100

2.5 62 95 0.05 062 062 4.3 82 126 0.1 102 - -

Cutting material HSS HSS Cutting material HSS HSS

Surface Vaporised Vaporised Surface Vaporised Vaporised

f steel 11056... 11059... f steel 11056... 11059...

700 Ident. No. Ident. No. 700 Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm

4.5 82 126 0.1 107 107 7 102 156 0.17 146 146

4.6 82 126 0.11 109 - - 7.5 102 156 0.19 153 153

4.7 82 126 0.11 111 - - 7.7 109 165 0.19 156 - -

4.8 87 132 0.11 114 - - 7.8 109 165 0.19 158 - -

4.9 87 132 0.11 116 - - 8 109 165 0.2 161 161

5 87 132 0.12 118 118 8.1 109 165 0.2 162 - -

5.1 87 132 0.12 119 - - 8.2 109 165 0.2 163 - -

5.2 87 132 0.12 121 - - 8.4 109 165 0.2 167 - -

5.3 87 132 0.12 123 - - 8.5 109 165 0.21 168 168

5.4 91 139 0.13 124 - - 9 115 175 0.21 175 175

5.5 91 139 0.13 125 125 9.5 115 175 0.22 182 - -

5.6 91 139 0.13 127 - - 9.8 121 184 0.22 187 - -

5.7 91 139 0.14 128 - - 10 121 184 0.22 190 - -

5.8 91 139 0.14 130 - - 10.2 121 184 0.22 192 - -

5.9 91 139 0.14 131 - - 10.5 121 184 0.23 197 - -

6 91 139 0.14 133 133 11 128 197 0.23 204 - -

6.1 97 148 0.15 134 - - 11.5 128 197 0.24 207 - -

6.2 97 148 0.15 135 - - 12 134 205 0.24 211 - -

6.3 97 148 0.15 137 - - 12.5 134 205 0.25 214 - -

6.4 97 148 0.16 139 - - 13 134 205 0.25 217 217

6.5 97 148 0.16 140 140 13.5 140 214 0.26 221 - -

6.6 97 148 0.16 141 - - 14 140 214 0.26 224 - -

6.7 97 148 0.16 142 - - 15 144 220 0.27 230 - -

6.8 102 156 0.17 144 - - 16 149 227 0.28 235 - -

a = Prod. Gr. 1AA

ORION = Prod. Gr. 1AP

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 40

0067_EN_2018_KERN[21841774]-n.indd 72 12/17/2018 3:31:40 PM