Page 16 - Icon Ridge Presents ORION

P. 16

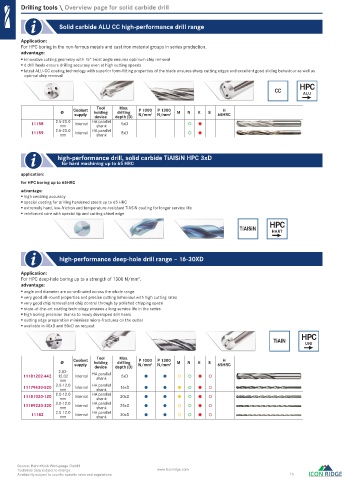

Drilling tools \ Overview page for solid carbide drill

Solid carbide ALU CC high-performance drill range

Application:

For HPC boring in the non-ferrous metals and cast iron material groups in series production.

advantage:

innovative cutting geometry with 15° twist angle ensures optimum chip removal

6 drill heels ensure drilling accuracy even at high cutting speeds

latest ALU-CC coating technology with superior form-fi tting properties of the blade ensures sharp cutting edges and excellent good sliding behaviour as well as

optimal chip removal

HPC

CC

ALU

Tool

Max.

H

drilling

Ø Coolant holding depth (D) P 1000 P 1300 2 M N K S 65HRC

supply

N/mm

N/mm

2

device

11158 2.5-20.0 Internal HA parallel 5xD

shank

mm

11159 2.5-20.0 Internal HA parallel 8xD

shank

mm

high-performance drill, solid carbide TiAISiN HPC 3xD

for hard machining up to 65 HRC

application:

for HPC boring up to 65HRC

advantage:

high centring accuracy

special coating for drilling hardened steels up to 65 HRC

extremely hard, low-friction and temperature-resistant TiASiN coating for longer service life

reinforced core with special tip and cutting chisel edge

HPC

TiAlSiN

HART

high-performance deep-hole drill range – 16-30XD

Application:

For HPC deep-hole boring up to a strength of 1300 N/mm . 2

advantage:

angle and diameter are co-ordinated across the whole range

very good all-round properties and precise cutting behaviour with high cutting rates

very good chip removal and chip control through by polished chipping space

state-of-the-art coating technology ensures a long service life in the series

high boring precision thanks to newly developed drill heels

cutting edge preparation minimises micro-fractures on the cutter

available in 40xD and 50xD on request

HPC

TiAlN UNI

Max.

Tool

H

drilling

Ø Coolant holding depth (D) P 1000 P 1300 2 M N K S 65HRC

N/mm

N/mm

supply

2

device

2.02-

11181202-442 12.02 Internal HA parallel 5xD

shank

mm

11179430-520 3.0-12.0 Internal HA parallel 16xD

mm

shank

11181020-120 2.0-12.0 Internal HA parallel 20xD

mm

shank

11189230-320 3.0-12.0 Internal HA parallel 25xD

mm

shank

11182 2.0-12.0 Internal HA parallel 30xD

shank

mm

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 16

0017_EN_2018_KERN[21841662]-f.indd 18 12/17/2018 3:31:18 PM