Page 231 - Icon Ridge Presents ORION

P. 231

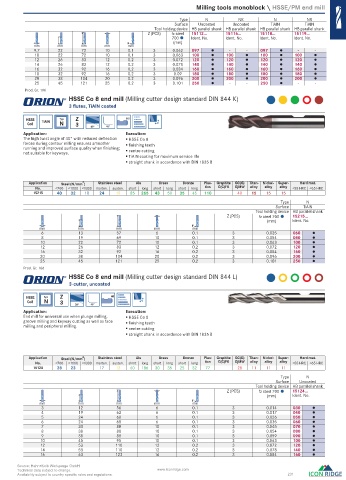

Milling tools monoblock \ HSSE/PM end mill

Type N NR N NR

Surface Uncoated Uncoated TiAlN TiAlN

Tool holding device HB parallel shank HB parallel shank HB parallel shank HB parallel shank

Z (PCS) fz steel 15112... 15116... 15118... 15119...

700 Ident. No. Ident. No. Ident. No. Ident. No.

(mm)

mm mm mm mm mm

9.7 22 72 10 0.1 3 0.062 097 - - 097 - -

10 22 72 10 0.1 3 0.063 100 100 100 100

12 26 83 12 0.2 3 0.072 120 120 120 120

14 26 83 12 0.2 3 0.078 140 140 140 140

16 32 92 16 0.2 3 0.084 160 160 160 160

18 32 92 16 0.2 3 0.09 180 180 180 180

20 38 104 20 0.2 3 0.096 200 200 200 200

25 45 121 25 0.2 3 0.101 250 - - 250 - -

Prod. Gr. 106

HSSE Co 8 end mill ( Milling cutter design standard DIN 844 K )

3 flutes, TiAlN coated

HSSE TiAlN Typ Z HB

Co8 N 3 45°

Application: Execution:

The high twist angle of 40° with reduced defl ection HSSE Co 8

forces during contour milling ensures smoother fi nishing teeth

running and improved surface quality when fi nishing; centre cutting

not suitable for keyways.

TiAIN coating for maximum service life

straight shank in accordance with DIN 1835 B

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

15215 40 32 18 24 19 85 265 43 50 35 45 110 40 15 15 15

Type N

Surface TiAlN

Tool holding device HB parallel shank

Z (PCS) fz steel 700 15215...

(mm) Ident. No.

mm mm mm mm mm

6 13 57 6 0.1 3 0.035 060

8 19 69 10 0.1 3 0.054 080

10 22 72 10 0.1 3 0.063 100

12 26 83 12 0.2 3 0.072 120

16 32 92 16 0.2 3 0.084 160

20 38 104 20 0.2 3 0.096 200

25 45 121 25 0.2 3 0.101 250

Prod. Gr. 106

HSSE Co 8 end mill ( Milling cutter design standard DIN 844 L )

3-cutter, uncoated

HSSE Typ Z HB

Co8 N 3 45°

Application: Execution:

End mill for universal use when plunge milling, HSSE Co 8

groove milling and keyway cutting as well as face fi nishing teeth

milling and peripheral milling.

centre cutting

straight shank in accordance with DIN 1835 B

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

15124 28 23 17 13 60 186 30 35 25 32 77 28 11 11 11

Type N

Surface Uncoated

Tool holding device HB parallel shank

Z (PCS) fz steel 700 15124...

(mm) Ident. No.

mm mm mm mm mm

3 12 56 6 0.1 3 0.014 030

4 19 63 6 0.1 3 0.017 040

5 24 68 6 0.1 3 0.026 050

6 24 68 6 0.1 3 0.035 060

7 30 80 10 0.1 3 0.045 070

8 38 88 10 0.1 3 0.054 080

9 38 88 10 0.1 3 0.059 090

10 45 95 10 0.1 3 0.063 100

12 53 110 12 0.2 3 0.072 120

14 53 110 12 0.2 3 0.078 140

16 63 123 16 0.2 3 0.084 160

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 231

0457_EN_2018_KERN[21847733]-k.indd 459 12/17/2018 3:32:45 PM