Page 93 - Industrial Tools Catalog (2)

P. 93

Zero point clamping system \ Info – zero point clamping system

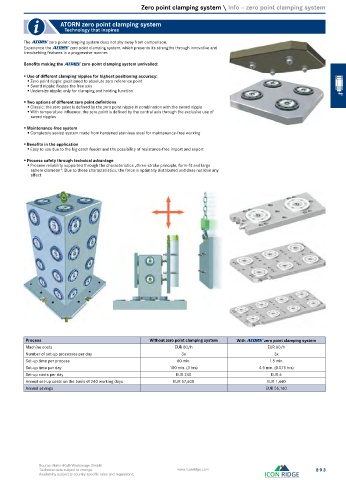

ATORN zero point clamping system

Technology that inspires

The a zero point clamping system does not shy away from comparison.

Experience the a zero point clamping system, which presents its strengths through innovative and

trendsetting features in a progressive manner.

Benefits making the a zero-point clamping system unrivalled:

Use of different clamping nipples for highest positioning accuracy:

Zero point nipple: positioned to absolute zero reference point

Sword nipple: fixates the free axis

Undersize nipple: only for clamping and holding function

Two options of different zero point definitions

Classic: the zero point is defined by the zero point nipple in combination with the sword nipple

With temperature influence: the zero point is defined by the central axis through the exclusive use of

sword nipples

Maintenance-free system

Completely sealed system made from hardened stainless steel for maintenance-free working

Benefits in the application

Easy to use due to the big catch feeder and the possibility of resistance-free import and export

Process safety through technical advantage

Process reliability supported through the characteristics „three-stroke principle, form-fit and large

sphere diameter“. Due to these characteristics, the force is optimally distributed and does not lose any

effect

Process Without zero point clamping system With a zero point clamping system

Machine costs EUR 80/h EUR 80/h

Number of set-up processes per day 3x 3x

Set-up time per process 60 min. 1.5 min.

Set-up time per day 180 min. (3 hrs) 4.5 min. (0.075 hrs)

Set-up costs per day EUR 240 EUR 6

Annual set-up costs on the basis of 240 working days EUR 57,600 EUR 1,440

Annual savings EUR 56,160

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 893

Availability subject to country specific rules and regulations.