Page 3 - RASSoW11Q - Tipper Operations-Rigid and Articulated Vehicle

P. 3

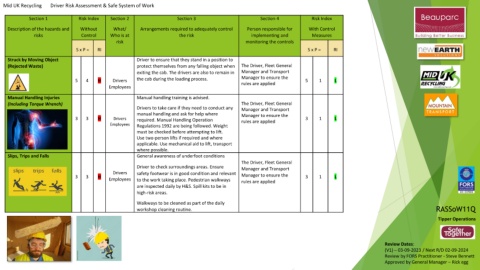

Mid UK Recycling Driver Risk Assessment & Safe System of Work

Section 1 Risk Index Section 2 Section 3 Section 4 Risk Index

Description of the hazards and Without What/ Arrangements required to adequately control Person responsible for With Control

risks Control Who is at the risk implementing and Measures

risk monitoring the controls

S x P = RI S x P = RI

Struck by Moving Object Driver to ensure that they stand in a position to

(Rejected Waste) protect themselves from any falling object when The Driver, Fleet General

exiting the cab. The drivers are also to remain in Manager and Transport

5 4 H Drivers the cab during the loading process. Manager to ensure the 5 1 L

rules are applied

Employees

Manual Handling Injuries Manual handling training is advised.

(Including Torque Wrench) The Driver, Fleet General

Drivers to take care if they need to conduct any Manager and Transport

manual handling and ask for help where Manager to ensure the

3 3 H Drivers required. Manual Handling Operation rules are applied 3 1 L

Employees Regulations 1992 are being followed. Weight

must be checked before attempting to lift.

Use two-person lifts if required and where

applicable. Use mechanical aid to lift, transport

where possible.

Slips, Trips and Falls General awareness of underfoot conditions

The Driver, Fleet General

Driver to check surroundings areas. Ensure Manager and Transport

Drivers safety footwear is in good condition and relevant

3 3 H Manager to ensure the 3 1 L

Employees to the work taking place. Pedestrian walkways rules are applied

are inspected daily by H&S. Spill kits to be in

high-risk areas.

Walkways to be cleaned as part of the daily

workshop cleaning routine. RASSoW11Q

Tipper Operations

Review Dates:

(V1) – 03-09-2023 / Next R/D 02-09-2024

Review by FORS Practitioner - Steve Bennett

Approved by General Manager – Rick egg