Page 18 - Industrial Technology EXTRA 15th March 2021

P. 18

EXTRA ‘FOCUS’ BEARINGS AND SLIDES

Miniature precision bearings meet the

needs of dental drill applications

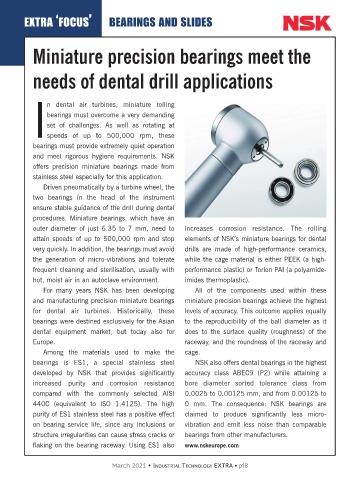

n dental air turbines, miniature rolling

bearings must overcome a very demanding

set of challenges. As well as rotating at

Ispeeds of up to 500,000 rpm, these

bearings must provide extremely quiet operation

and meet rigorous hygiene requirements. NSK

offers precision miniature bearings made from

stainless steel especially for this application.

Driven pneumatically by a turbine wheel, the

two bearings in the head of the instrument

ensure stable guidance of the drill during dental

procedures. Miniature bearings, which have an

outer diameter of just 6.35 to 7 mm, need to increases corrosion resistance. The rolling

attain speeds of up to 500,000 rpm and stop elements of NSK’s miniature bearings for dental

very quickly. In addition, the bearings must avoid drills are made of high-performance ceramics,

the generation of micro-vibrations and tolerate while the cage material is either PEEK (a high-

frequent cleaning and sterilisation, usually with performance plastic) or Torlon PAI (a polyamide-

hot, moist air in an autoclave environment. imides thermoplastic).

For many years NSK has been developing All of the components used within these

and manufacturing precision miniature bearings miniature precision bearings achieve the highest

for dental air turbines. Historically, these levels of accuracy. This outcome applies equally

bearings were destined exclusively for the Asian to the reproducibility of the ball diameter as it

dental equipment market, but today also for does to the surface quality (roughness) of the

Europe. raceway, and the roundness of the raceway and

Among the materials used to make the cage.

bearings is ES1, a special stainless steel NSK also offers dental bearings in the highest

developed by NSK that provides significantly accuracy class ABEC9 (P2) while attaining a

increased purity and corrosion resistance bore diameter sorted tolerance class from

compared with the commonly selected AISI 0.0025 to 0.00125 mm, and from 0.00125 to

440C (equivalent to ISO 1.4125). The high 0 mm. The consequence: NSK bearings are

purity of ES1 stainless steel has a positive effect claimed to produce significantly less micro-

on bearing service life, since any inclusions or vibration and emit less noise than comparable

structure irregularities can cause stress cracks or bearings from other manufacturers.

flaking on the bearing raceway. Using ES1 also www.nskeurope.com

March 2021 • INDUSTRIAL TECHNOLOGY EXTRA • p18