Page 4 - Industrial Technology EXTRA 7th June 2021

P. 4

COUPLINGS..

Modified couplings prove their

worth in diamond polishing

When a UK diamond toolmaking machine manufacturer needed a custom coupling

for use on its line of new extreme material finishing machines, it turned to Huco for

a precision solution. Huco was able to meet the requirements by modifying a

membrane-type coupling with special bore sizes and keyways, and ship it to the

OEM cost-effectively in the relatively small quantities required.

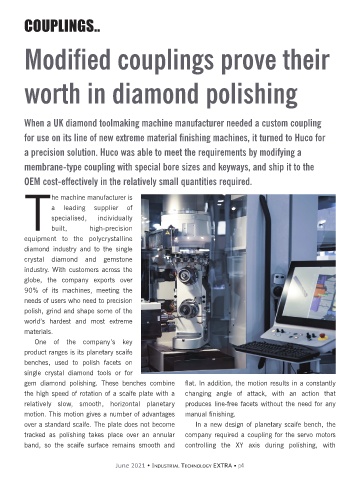

he machine manufacturer is

a leading supplier of

specialised, individually

Tbuilt, high-precision

equipment to the polycrystalline

diamond industry and to the single

crystal diamond and gemstone

industry. With customers across the

globe, the company exports over

90% of its machines, meeting the

needs of users who need to precision

polish, grind and shape some of the

world’s hardest and most extreme

materials.

One of the company’s key

product ranges is its planetary scaife

benches, used to polish facets on

single crystal diamond tools or for

gem diamond polishing. These benches combine flat. In addition, the motion results in a constantly

the high speed of rotation of a scaife plate with a changing angle of attack, with an action that

relatively slow, smooth, horizontal planetary produces line-free facets without the need for any

motion. This motion gives a number of advantages manual finishing.

over a standard scaife. The plate does not become In a new design of planetary scaife bench, the

tracked as polishing takes place over an annular company required a coupling for the servo motors

band, so the scaife surface remains smooth and controlling the XY axis during polishing, with

June 2021 • INDUSTRIAL TECHNOLOGY EXTRA • p4