Page 8 - Industrial Technology EXTRA 27th July 2020

P. 8

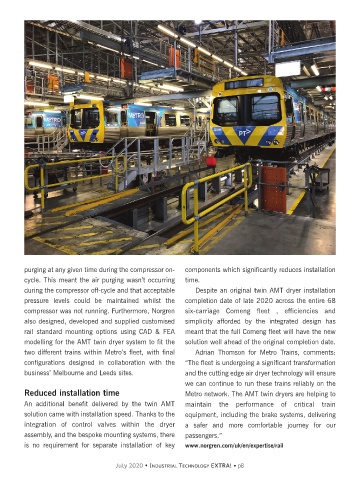

purging at any given time during the compressor on- components which significantly reduces installation

cycle. This meant the air purging wasn’t occurring time.

during the compressor off-cycle and that acceptable Despite an original twin AMT dryer installation

pressure levels could be maintained whilst the completion date of late 2020 across the entire 68

compressor was not running. Furthermore, Norgren six-carriage Comeng fleet , efficiencies and

also designed, developed and supplied customised simplicity afforded by the integrated design has

rail standard mounting options using CAD & FEA meant that the full Comeng fleet will have the new

modelling for the AMT twin dryer system to fit the solution well ahead of the original completion date.

two different trains within Metro’s fleet, with final Adrian Thomson for Metro Trains, comments:

configurations designed in collaboration with the “The fleet is undergoing a significant transformation

business’ Melbourne and Leeds sites. and the cutting edge air dryer technology will ensure

we can continue to run these trains reliably on the

Reduced installation time Metro network. The AMT twin dryers are helping to

An additional benefit delivered by the twin AMT maintain the performance of critical train

solution came with installation speed. Thanks to the equipment, including the brake systems, delivering

integration of control valves within the dryer a safer and more comfortable journey for our

assembly, and the bespoke mounting systems, there passengers.”

is no requirement for separate installation of key www.norgren.com/uk/en/expertise/rail

July 2020 • INDUSTRIAL TECHNOLOGY EXTRA! • p8