Page 8 - Industrial_Technology_EXTRA_October_26th_2020_Classical

P. 8

HYGIENIC MANUFACTURING...

Latest flow sensor offers

multi-parameter analysis

Hygienic manufacturing focus on cleanliness and product quality, in some cases to

the point where valuable product is disposed of in the process of ensuring the

necessary standards are maintained. To reduce waste, the challenge is to quickly and

accurately identify different fluids in the process pipework, which can now be

achieved at the same time as measuring flowrates

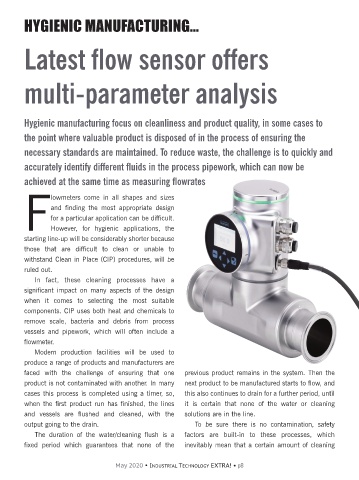

lowmeters come in all shapes and sizes

and finding the most appropriate design

for a particular application can be difficult.

FHowever, for hygienic applications, the

starting line-up will be considerably shorter because

those that are difficult to clean or unable to

withstand Clean in Place (CIP) procedures, will be

ruled out.

In fact, these cleaning processes have a

significant impact on many aspects of the design

when it comes to selecting the most suitable

components. CIP uses both heat and chemicals to

remove scale, bacteria and debris from process

vessels and pipework, which will often include a

flowmeter.

Modern production facilities will be used to

produce a range of products and manufacturers are

faced with the challenge of ensuring that one previous product remains in the system. Then the

product is not contaminated with another. In many next product to be manufactured starts to flow, and

cases this process is completed using a timer, so, this also continues to drain for a further period, until

when the first product run has finished, the lines it is certain that none of the water or cleaning

and vessels are flushed and cleaned, with the solutions are in the line.

output going to the drain. To be sure there is no contamination, safety

The duration of the water/cleaning flush is a factors are built-in to these processes, which

fixed period which guarantees that none of the inevitably mean that a certain amount of cleaning

May 2020 • INDUSTRIAL TECHNOLOGY EXTRA! • p8