Page 35 - Chiron 2024

P. 35

ADVERTORIAL FEATURE

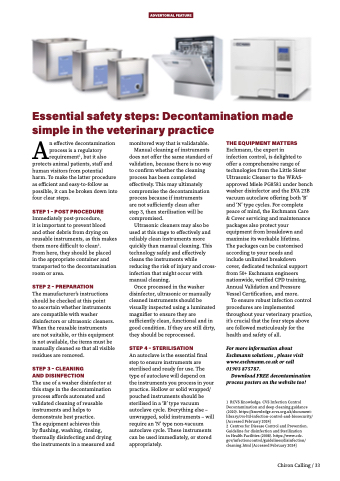

Essential safety steps: Decontamination made

Asimple in the veterinary practice n effective decontamination monitored way that is validatable.

process is a regulatory Manual cleaning of instruments

1

requirement , but it also does not offer the same standard of

THE EQUIPMENT MATTERS

Eschmann, the expert in

infection control, is delighted to offer a comprehensive range of technologies from the Little Sister Ultrasonic Cleaner to the WRAS- approved Miele PG8581 under bench washer disinfector and the EVA 23B vacuum autoclave offering both ‘B’ and ‘N’ type cycles. For complete peace of mind, the Eschmann Care & Cover servicing and maintenance packages also protect your equipment from breakdown and maximise its workable lifetime.

The packages can be customised according to your needs and

include unlimited breakdown

cover, dedicated technical support from 50+ Eschmann engineers nationwide, verified CPD training, Annual Validation and Pressure Vessel Certification, and more.

To ensure robust infection control procedures are implemented throughout your veterinary practice, it’s crucial that the four steps above are followed meticulously for the health and safety of all.

For more information about Eschmann solutions , please visit www.eschmann.co.uk or call 01903 875787.

Download FREE decontamination process posters on the website too!

1 RCVS Knowledge. CVS Infection Control Decontamination and deep cleaning guidance (2020). https://knowledge.rcvs.org.uk/document- library/cvs-ltd-infection-control-and-biosecurity/ [Accessed February 2024]

2 Centres for Disease Control and Prevention. Guideline for disinfection and Sterilization

in Health Facilities (2008). https://www.cdc. gov/infectioncontrol/guidelines/disinfection/ cleaning.html [Accessed February 2024]

protects animal patients, staff and human visitors from potential harm. To make the latter procedure as efficient and easy-to-follow as possible, it can be broken down into four clear steps.

STEP 1 – POST PROCEDURE

Immediately post-procedure,

it is important to prevent blood

and other debris from drying on reusable instruments, as this makes them more difficult to clean2.

From here, they should be placed in the appropriate container and transported to the decontamination room or area.

STEP 2 – PREPARATION

The manufacturer’s instructions should be checked at this point

to ascertain whether instruments are compatible with washer disinfectors or ultrasonic cleaners. When the reusable instruments are not suitable, or this equipment is not available, the items must be manually cleaned so that all visible residues are removed.

STEP 3 – CLEANING

AND DISINFECTION

The use of a washer disinfector at this stage in the decontamination process affords automated and validated cleaning of reusable instruments and helps to demonstrate best practice.

The equipment achieves this

by flushing, washing, rinsing, thermally disinfecting and drying the instruments in a measured and

validation, because there is no way to confirm whether the cleaning process has been completed effectively. This may ultimately compromise the decontamination process because if instruments

are not sufficiently clean after step 3, then sterilisation will be compromised.

Ultrasonic cleaners may also be used at this stage to effectively and reliably clean instruments more quickly than manual cleaning. This technology safely and effectively cleans the instruments while reducing the risk of injury and cross- infection that might occur with manual cleaning.

Once processed in the washer disinfector, ultrasonic or manually cleaned instruments should be visually inspected using a luminated magnifier to ensure they are sufficiently clean, functional and in good condition. If they are still dirty, they should be reprocessed.

STEP 4 – STERILISATION

An autoclave is the essential final step to ensure instruments are sterilised and ready for use. The type of autoclave will depend on the instruments you process in your practice. Hollow or solid wrapped/ pouched instruments should be sterilised in a ‘B’ type vacuum autoclave cycle. Everything else – unwrapped, solid instruments – will require an ‘N’ type non-vacuum autoclave cycle. These instruments can be used immediately, or stored appropriately.

Chiron Calling / 33