Page 5 - Concrete-Technology-Interacted_Book_Prof-MIK_Neat

P. 5

1/6 Fresh concrete

Table 1.1 Common single-point workability tests

Test Principle Comments

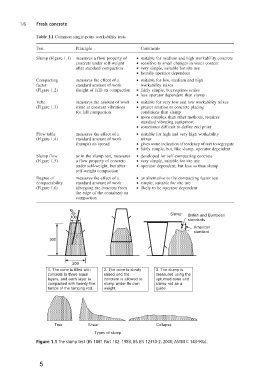

Slump (Figure 1.1) measures a flow property of • suitable for medium and high workability concrete

concrete under self-weight • sensitive to small changes in water content

after standard compaction • very simple, suitable for site use

• heavily operator dependent

Compacting measures the effect of a

factor standard amount of work • suitable for low, medium and high

(Figure 1.2) (height of fall) on compaction workability mixes

Vebe measures the amount of work • fairly simple, but requires scales

(Figure 1.3) (time at constant vibration) • less operator dependent than slump

for full compaction

• suitable for very low and low workability mixes

Flow table measures the effect of a • greater relation to concrete placing

(Figure 1.4) standard amount of work

(bumps) on spread conditions than slump

Slump flow • more complex than other methods, requires

(Figure 1.5) as in the slump test, measures

a flow property of concrete standard vibrating equipment

Degree of under self-weight, but after • sometimes difficult to define end point

compactability self-weight compaction

(Figure 1.6) • suitable for high and very high workability

measures the effect of a mixes

standard amount of work

(dropping the concrete from • gives some indication of tendency of mix to segregate

the edge of the container) on • fairly simple, but, like slump, operator dependent

compaction

• developed for self-compacting concrete

• very simple, suitable for site use

• operator dependent, but less so than slump

• an alternative to the compacting factor test

• simple, suitable for site use

• likely to be operator dependent

100 Slump: British and European

300 standards

American

standard

200 2. The cone is slowly 3. The slump is

raised and the measured using the

1. The cone is filled with concrete is allowed to upturned cone and

concrete in three equal slump under its own slump rod as a

layers, and each layer is weight. guide

compacted with twenty-five

tamps of the tamping rod.

True Shear Collapse

Types of slump

Figure 1.1 The slump test (BS 1881 Part 102: 1983; BS EN 12350-2: 2000; ASTM C 143-90a).

5