Page 29 - Green Builder's Resilient Housing Design Guide 2019

P. 29

wall might be a good pressure washing.

The Roman Pantheon, the medieval SLAM TEST: ICF walls can take a beating

cathedrals of Europe, the Hoover Dam—

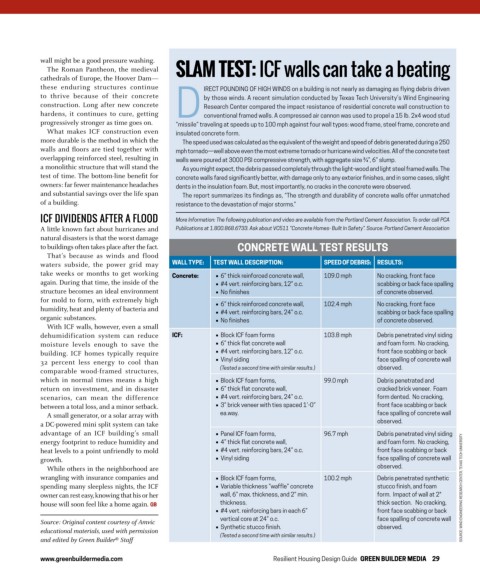

these enduring structures continue IRECT POUNDING OF HIGH WINDS on a building is not nearly as damaging as flying debris driven

to thrive because of their concrete by those winds. A recent simulation conducted by Texas Tech University’s Wind Engineering

construction. Long after new concrete Research Center compared the impact resistance of residential concrete wall construction to

hardens, it continues to cure, getting D conventional framed walls. A compressed air cannon was used to propel a 15 lb. 2x4 wood stud

progressively stronger as time goes on. “missile” traveling at speeds up to 100 mph against four wall types: wood frame, steel frame, concrete and

What makes ICF construction even insulated concrete form.

more durable is the method in which the The speed used was calculated as the equivalent of the weight and speed of debris generated during a 250

walls and floors are tied together with mph tornado—well above even the most extreme tornado or hurricane wind velocities. All of the concrete test

overlapping reinforced steel, resulting in walls were poured at 3000 PSI compressive strength, with aggregate size ¾”, 6” slump.

a monolithic structure that will stand the As you might expect, the debris passed completely through the light-wood and light steel framed walls. The

test of time. The bottom-line benefit for concrete walls fared significantly better, with damage only to any exterior finishes, and in some cases, slight

owners: far fewer maintenance headaches dents in the insulation foam. But, most importantly, no cracks in the concrete were observed.

and substantial savings over the life span The report summarizes its findings as, “The strength and durability of concrete walls offer unmatched

of a building. resistance to the devastation of major storms.”

ICF DIVIDENDS AFTER A FLOOD More Information: The following publication and video are available from the Portland Cement Association. To order call PCA

A little known fact about hurricanes and Publications at 1.800.868.6733. Ask about VC511 “Concrete Homes- Built In Safety”. Source: Portland Cement Association

natural disasters is that the worst damage

to buildings often takes place after the fact. CONCRETE WALL TEST RESULTS

That’s because as winds and flood

waters subside, the power grid may WALL TYPE: TEST WALL DESCRIPTION: SPEED OF DEBRIS: RESULTS:

take weeks or months to get working Concrete: ■ ■ 6” thick reinforced concrete wall, 109.0 mph No cracking, front face

again. During that time, the inside of the ■ ■ #4 vert. reinforcing bars, 12” o.c. scabbing or back face spalling

structure becomes an ideal environment ■ ■ No finishes of concrete observed.

for mold to form, with extremely high

■ ■ 6” thick reinforced concrete wall, 102.4 mph No cracking, front face

humidity, heat and plenty of bacteria and

■ ■ #4 vert. reinforcing bars, 24” o.c. scabbing or back face spalling

organic substances.

■ ■ No finishes of concrete observed.

With ICF walls, however, even a small

dehumidification system can reduce ICF: ■ ■ Block ICF foam forms 103.8 mph Debris penetrated vinyl siding

moisture levels enough to save the ■ ■ 6” thick flat concrete wall and foam form. No cracking,

building. ICF homes typically require ■ ■ #4 vert. reinforcing bars, 12” o.c. front face scabbing or back

32 percent less energy to cool than ■ ■ Vinyl siding face spalling of concrete wall

comparable wood-framed structures, (Tested a second time with similar results.) observed.

which in normal times means a high ■ ■ Block ICF foam forms, 99.0 mph Debris penetrated and

return on investment, and in disaster ■ ■ 6” thick flat concrete wall, cracked brick veneer. Foam

scenarios, can mean the difference ■ ■ #4 vert. reinforcing bars, 24” o.c. form dented. No cracking,

between a total loss, and a minor setback. ■ ■ 3” brick veneer with ties spaced 1’-0” front face scabbing or back

A small generator, or a solar array with ea.way. face spalling of concrete wall

a DC-powered mini split system can take observed.

advantage of an ICF building’s small ■ ■ Panel ICF foam forms, 96.7 mph Debris penetrated vinyl siding

energy footprint to reduce humidity and ■ ■ 4” thick flat concrete wall, and foam form. No cracking,

heat levels to a point unfriendly to mold ■ ■ #4 vert. reinforcing bars, 24” o.c. front face scabbing or back

growth. ■ ■ Vinyl siding face spalling of concrete wall

While others in the neighborhood are observed.

wrangling with insurance companies and ■ ■ Block ICF foam forms, 100.2 mph Debris penetrated synthetic

spending many sleepless nights, the ICF ■ ■ Variable thickness “waffle” concrete stucco finish, and foam SOURCE: WIND ENGINEERING RESEARCH CENTER, TEXAS TECH UNIVERSITY

owner can rest easy, knowing that his or her wall, 6” max. thickness, and 2” min. form. Impact of wall at 2"

house will soon feel like a home again. GB thickness. thick section. No cracking,

■ #4 vert. reinforcing bars in each 6” front face scabbing or back

■

Source: Original content courtesy of Amvic vertical core at 24” o.c. face spalling of concrete wall

educational materials, used with permission ■ ■ Synthetic stucco finish. observed.

®

and edited by Green Builder Staff (Tested a second time with similar results.)

www.greenbuildermedia.com Resilient Housing Design Guide GREEN BUILDER MEDIA 29