Page 17 - GB Building Science Ebook 2019

P. 17

FLOOD-RESISTANT AIMING FOR ZERO

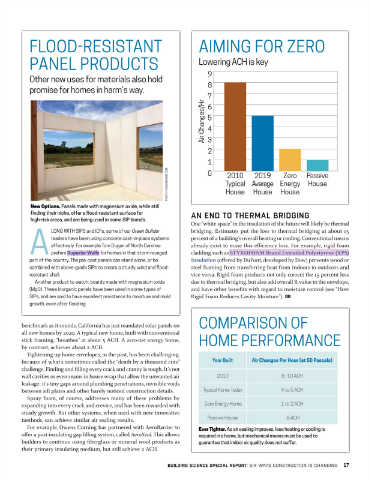

PANEL PRODUCTS Lowering ACH is key

9

Other new uses for materials also hold

promise for homes in harm’s way. 8

7

Air Changes/Hr 5

6

4

3

2

1

PHOTO: YUNIONBOARD.COM Typical Average Energy House

0

2019

Zero

Passive

2010

House

House

House

New Options. Panels made with magnesium oxide, while still

finding their niche, offer a flood-resistant surface for AN END TO THERMAL BRIDGING

high-risk areas, and are being used in some SIP brands.

One “white space” in the insulation of the future will likely be thermal

LONG WITH SIPS and ICFs, some of our Green Builder bridging. Estimates put the loss to thermal bridging at about 15

readers have been using concrete cast-in-place systems percent of a building’s overall heating or cooling. Conventional means

effectively. For example Tom Dugan of North Carolina already exist to erase this efficiency loss. For example, rigid foam

A prefers Superior Walls for homes in that storm ravaged cladding such as STYROFOAM Brand Extruded Polystyrene (XPS)

part of the country. The pre-cast panels can stand alone, or be Insulation (offered by DuPont, developed by Dow) prevents wood or

combined with above-grade SIPs to create a sturdy, wind and flood- steel framing from transferring heat from indoors to outdoors and

resistant shell. vice versa. Rigid foam products not only correct the 15 percent loss

Another product to watch: boards made with magnesium oxide due to thermal bridging, but also add overall R-value to the envelope,

(MgO). These inorganic panels have been used in some types of and have other benefits with regard to moisture control (see “How

SIPs, and are said to have excellent resistance to moisture and mold Rigid Foam Reduces Cavity Moisture”). GB

growth, even after flooding.

COMPARISON OF

benchmark as it sounds. California has just mandated solar panels on

all new homes by 2020. A typical new home, built with conventional

stick framing, “breathes” at about 5 ACH. A zero-net energy home, HOME PERFORMANCE

by contrast, achieves about 2 ACH.

Tightening up home envelopes, in the past, has been challenging,

because of what’s sometimes called the “death by a thousand cuts” Year Built Air Changes Per Hour (at 50 Pascals)

challenge. Finding and filling every crack and cranny is tough. It’s not

wall cavities or even seams in house wrap that allow the unwanted air 2010 8 -10 ACH

leakage: it’s tiny gaps around plumbing penetrations, invisible voids

between sill plates and other barely noticed construction details. Typical Home Today 4 to 5 ACH

Spray foam, of course, addresses many of these problems by

expanding into every crack and crevice, and has been rewarded with Zero Energy Home 1 to 2 ACH

steady growth. But other systems, when used with new innovative

methods, can achieve similar air sealing results. Passive House .6 ACH

For example, Owens Corning has partnered with AeroBarrier to Ever Tighter. As air sealing improves, less heating or cooling is

offer a post-insulating gap filling system, called AeroSeal. This allows required in a home, but mechanical means must be used to

builders to continue using fiberglass or mineral wool products as guarantee that indoor air quality does not suffer.

their primary insulating medium, but still achieve 2 ACH.

BUILDING SCIENCE SPECIAL REPORT: SIX WAYS CONSTRUCTION IS CHANGING 17