Page 1049 - Master Catalog 2017, Inch

P. 1049

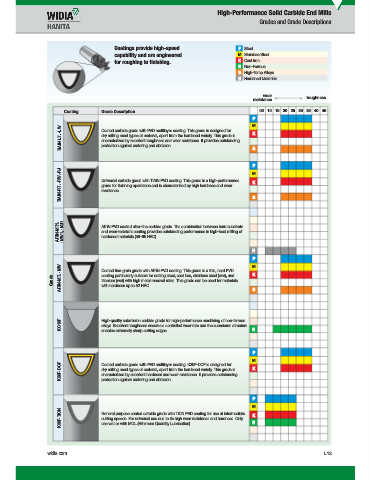

High-Performance Solid Carbide End Mills

Grades and Grade Descriptions

Coatings provide high-speed P Steel

capability and are engineered M Stainless Steel

for roughing to fi nishing. K Cast Iron

N Non-Ferrous

S High-Temp Alloys

H Hardened Materials

wear

resistance toughness

Coating Grade Description 05 10 15 20 25 30 35 40 45

P

M

TiAlN-LT, -LW Coated carbide grade with PVD multilayer coating. This grade is designed for K S

dry milling most types of material, apart from the hardened variety. This grade is

characterized by excellent toughness and wear resistance. It provides outstanding

protection against cratering and abrasion.

P

TiAlN-RT, -RW,-RJ Universal carbide grade with TiAlN PVD coating. This grade is a high-performance K S

M

grade for fi nishing operations and is characterized by high hardness and wear

resistance.

AlTiN-MT1, -MW1, -MJ1 AlTiN PVD coated ultra-fi ne carbide grade. The combination between hard substrate

and wear-resistant coating provides outstanding performance in high-feed milling of

hardened materials (58–65 HRC).

H

P

AlTiN-MT, -MW Coated fi ne-grain grade with AlTiN PVD coating. This grade is a thin, hard PVD K

M

Grade titanium (wet) with high metal removal rates. This grade can be used for materials S

coating particularly suitable for cutting steel, cast iron, stainless steel (wet), and

with hardness up to 52 HRC.

KC10F High-quality submicron carbide grade for high-performance machining of non-ferrous N

alloys. Excellent toughness ensures a controlled wear rate and the submicron structure

enables extremely sharp cutting edges.

P

M

K30F-DCF dry milling most types of material, apart from the hardened variety. This grade is K

Coated carbide grade with PVD multilayer coating. K30F-DCF is designed for

characterized by excellent hardness and wear resistance. It provides outstanding

protection against cratering and abrasion.

P

M

K30F-TiCN General purpose coated carbide grade with TiCN PVD coating for use at intermediate K

cutting speeds. For universal use due to its high wear resistance and hardness. Only

N

use wet or with MQL (Minimum Quantity Lubrication).

widia.com L13

MI

h

M

3

1

P

5

N

REBRAND

2015

10

S

lidE

6

V i WID M

1

dMilli

L012

L013

i

S

WID_Master16_SolidEndMilling_SectionIntro_L012_L013_MInch_REBRAND.indd 13 L L V i WID M 16 S lidE dMilli S i I I L012 L013 MI h REBRANDN b 102015135PM

b 11/11/15 9:35 AM