Page 1086 - Master Catalog 2017, Inch

P. 1086

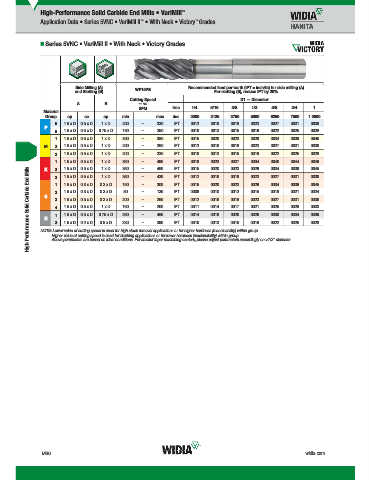

High-Performance Solid Carbide End Mills • VariMill ™

Application Data • Series 5VNC • VariMill II • With Neck • Victory Grades

™

™

Series 5VNC • VariMill II • With Neck • Victory Grades

Side Milling (A) Recommended feed per tooth (IPT = inch/th) for side milling (A).

and Slotting (B) WP15PE For slotting (B), reduce IPT by 20%.

Cutting Speed D1 — Diameter

A B — vc

SFM frac. 1/4 5/16 3/8 1/2 5/8 3/4 1

Material

Group ap ae ap min max dec. .2500 .3125 .3750 .5000 .6250 .7500 1.0000

5 1.5 x D 0.5 x D 1 x D 200 – 330 IPT .0012 .0016 .0018 .0023 .0027 .0031 .0036

P

6 1.5 x D 0.5 x D 0.75 x D 160 – 250 IPT .0010 .0013 .0015 .0019 .0022 .0025 .0028

1 1.5 x D 0.5 x D 1 x D 300 – 380 IPT .0015 .0020 .0023 .0029 .0034 .0039 .0045

M 2 1.5 x D 0.5 x D 1 x D 200 – 260 IPT .0012 .0016 .0018 .0023 .0027 .0031 .0036

3 1.5 x D 0.5 x D 1 x D 200 – 230 IPT .0010 .0013 .0015 .0019 .0022 .0025 .0028

1 x D

1 2 3 1 1.5 x D 0.5 x D 0.3 x D 390 – – – – 490 IPT .0018 .0023 .0027 .0034 .0040 .0044 .0049

.0020

.0023

1.5 x D

460

1 x D

360

0.5 x D

.0015

IPT

.0029

High-Performance Solid Carbide End Mills NOTE: Lower value of cutting speed is used for high stock removal applications or for higher hardness (machinability) within group. .0018 .0021 .0024

.0045

.0039

.0034

K

.0031

0.5 x D

.0027

.0018

IPT

.0012

430

360

.0023

.0036

.0016

1.5 x D

1 x D

160

300

.0039

.0045

.0020

0.3 x D

.0029

.0015

.0023

IPT

.0034

1.5 x D

.0010

.0012

80

IPT

130

–

.0015

.0008

0.3 x D

1.5 x D

0.3 x D

2

S

.0027

.0016

0.3 x D

IPT

200

.0018

.0023

260

.0012

.0031

.0036

0.3 x D

–

1.5 x D

3

1.5 x D

.0017

IPT

.0014

.0011

0.5 x D

.0028

.0033

.0025

–

1 x D

160

200

.0021

4

1.5 x D

.0034

.0018

.0020

.0026

.0030

.0039

460

0.5 x D

IPT

260

–

0.75 x D

.0014

1

H

.0010

390

IPT

.0025

1.5 x D

.0022

–

.0019

0.5 x D

230

0.2 x D

.0013

.0015

.0028

2

Higher value of cutting speed is used for finishing applications or for lower hardness (machinability) within group.

Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordingly on >1/2" diameter.

M30 widia.com

hP

V V

16 S lidE dMilli

f

Hi hP f

Hi

i i

M

S

M031

6

b 9 20159 12AM

1

M030 M031 Mi h REBRANDN

WID M

M030

dMilli

lidE

WID

L L WID_Master16_SolidEndMilling_HighPerformance_M030_M031_Minch_REBRAND.indd 30 Mi h REBRANDN b 9 20159 1 2AM 11/11/15 9:37 AM