Page 1100 - Master Catalog 2017, Inch

P. 1100

High-Performance Solid Carbide End Mills •

III

R

III

III

III

R

ER

ER

R

R

R

i

i

i

i

ill

i

R

R

ll

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

ER

ER

R

R

R

R

R

R

R

i

i

Mi

M

M

ill

i

i

ill

ill

i

M

R

R

R

Va Vi i Mi i i i i i i i ill III ™ ™ ™ ER

Vi

R

R

Mi

Mill

r

R

R

i

i

i

i

i

i

i

i

ill

ill

i

i

ii

i

i

VariMill III ER

VariMill III ER

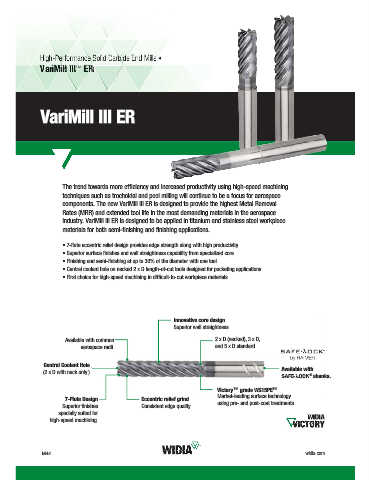

The trend towards more effi ciency and increased productivity using high-speed machining

techniques such as trochoidal and peel milling will continue to be a focus for aerospace

components. The new VariMill III ER is designed to provide the highest Metal Removal

Rates (MRR) and extended tool life in the most demanding materials in the aerospace

industry. VariMill III ER is designed to be applied in titanium and stainless steel workpiece

materials for both semi-fi nishing and fi nishing applications.

• 7-fl ute eccentric relief design provides edge strength along with high productivity.

• Superior surface fi nishes and wall straightness capability from specialized core.

• Finishing and semi-fi nishing at up to 30% of the diameter with one tool.

• Central coolant hole on necked 2 x D length-of-cut tools designed for pocketing applications.

• First choice for high-speed machining in diffi cult-to-cut workpiece materials.

Innovative core design

Superior wall straightness.

Available with common 2 x D (necked), 3 x D,

aerospace radii. and 5 x D standard.

®

Central Coolant Hole

(2 x D with neck only.) Available with

®

SAFE-hOCK shanks.

Victory™ grade WS15PE™

Market-leading surface technology

7-Flute Design Eccentric relief grind

Superior fi nishes Consistent edge quality. using pre- and post-coat treatments.

specially suited for

high-speed machining.

M44 widia.com

M044 M045 Mi h REBRANDN

f

M044

b 10 20152 27PM

lidE

M045

V V

hP

WID M

i i

WID

16 S lidE dMilli

M

1

Hi

Hi hP f

dMilli

6

S

L L WID_Master16_SolidEndMilling_HighPerformance_M044_M045_Minch_REBRAND.indd 44 Mi h REBRANDN b 10 20152 2 7PM 11/11/15 9:38 AM