Page 1312 - Master Catalog 2017, Inch

P. 1312

Choosing the Correct Production

Holemaking

Added Value for Your Performance

Increase of Productivity and Effi ciency Control of Total Tooling Costs

• Material and application-specifi c solutions. • High tool utilization through material and application-

• Maximum metal removal rates and repeatability. specifi c solutions.

• Standardized design platforms for special tools based • Process-safe regrinding service.

on “proven solutions” for individual optimizations and • Reduction of stocks through effi cient modular concepts.

combination tools. • Multiple platforms per application to achieve the most

cost-effi cient solution.

Optimized Purchase

• Broad selection of holemaking tools.

• Integrated into a full range of cutting tools

and service offers.

• Onsite service for an effi cient development and

implementation of machining solutions.

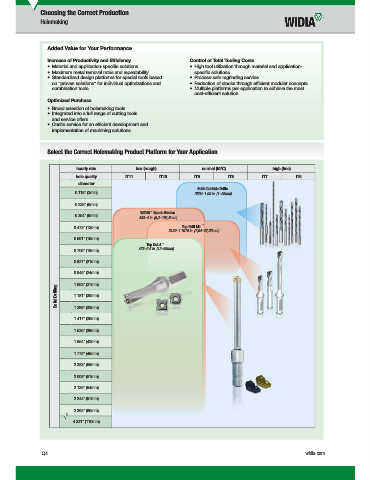

Select the Correct Holemaking Product Platform for Your Application

hourly rate low (rough) normal (M/C) high (fi ne)

hole quality IT11 IT10 IT9 IT8 IT7 IT6

diameter

Solid Carbide Drills

0.118" (3mm) .0394–1.00 in. (1–25mm)

0.236" (6mm)

WIDIA ™ Spade Blades

0.354" (9mm) .438–4 in. (9,2–101,6mm)

0.472" (12mm) Top Drill M1 ™

.3125–1.1010 in. (7,94–27,99mm)

0.591" (15mm)

Top Cut 4 ™

0.709" (18mm) .473–2.5 in. (12–68mm)

0.827" (21mm)

0.945" (24mm)

1.063" (27mm)

Solid Drilling 1.181" (30mm)

1.299" (33mm)

1.417" (36mm)

1.535" (39mm)

1.654" (42mm)

1.772" (45mm)

2.283" (58mm)

2.008" (51mm)

2.126" (54mm)

2.244" (57mm)

2.362" (60mm)

4.331" (110mm)

Q4 widia.com

V

i

WID M

S

ki

16 H l

Q004 Q005 Mi

I

i

L WID_Master16_Holemaking_SectionIntro_Q004_Q005_Minch_REBRAND.indd 4 h REBRANDN b 13 20159 50AM 11/13/15 9:56 AM