Page 1453 - Master Catalog 2017, Inch

P. 1453

Solid Carbide Drills

General Application Instructions

(continued)

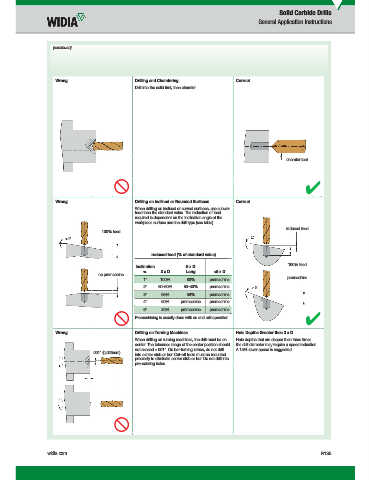

Wrong Drilling and Chamfering Correct

Drill into the solid fi rst, then chamfer.

chamfer tool

[

Wrong Drilling on Inclined or Rounded Surfaces Correct

When drilling on inclined or curved surfaces, use a lower

feed than the standard value. The reduction of feed

required is dependent on the inclination angle of the

workpiece surface and the drill type (see table).

reduced feed

100% feed

>1°

reduced feed (% of standard value)

100% feed

inclination 5 x D

_ 3 x D Long <5 x D

no premachine

premachine

1° 100% 80% premachine

2° 80–50% 80–50% premachine

3° 65% 50% premachine

4° 50% premachine premachine

premachine

6°

30%

premachine

[ Premachining is usually done with an end mill operation.

Wrong Drilling on Turning Machines Hole Depths Greater than 3 x D

When drilling on turning machines, the drill must be on Hole depths that are deeper than three times

center. The tolerance range of the center position should the drill diameter may require a speed reduction.

not exceed ±.001". On bar-turning lathes, do not drill A 15% lower speed is suggested.

.001" (0,025mm)

into center stub or bur. Cut-off tools must be mounted

precisely to eliminate center stub or bur. Do not drill into

pre-existing holes.

[

widia.com R135

10/29/15 1:08 PM

WID_Master16_Holemaking_SolidCarbideDrills_R134_R135_Minch_REBRAND.indd 135 L V i WID M 16 H l ki S lidC bid Dill R134 R135 Mi h REBRANDO b 132015426PM