Page 1521 - Master Catalog 2017, Inch

P. 1521

Indexable Drills

Grades and Grade Descriptions

P Steel

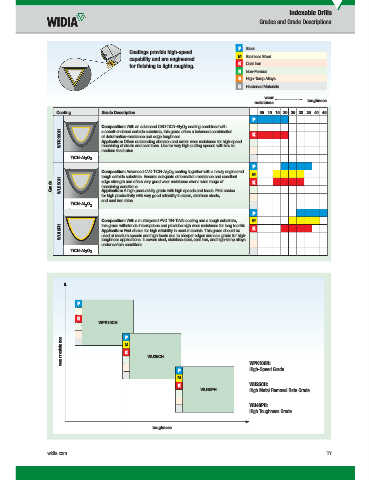

Coatings provide high-speed

M Stainless Steel

capability and are engineered

K Cast Iron

for finishing to light roughing.

N Non-Ferrous

S High-Temp Alloys

H Hardened Materials

wear

resistance toughness

Coating Grade Description 05 10 15 20 25 30 35 40 45

P

Composition: With an advanced CVD TiCN-Al O coating combined with

2 3

WPK10CH of deformation-resistance and edge toughness. K

a cobalt-enriched carbide substrate, this grade offers a balanced combination

Application: Offers outstanding abrasion and crater wear resistance for high-speed

machining of steels and cast irons. Use for very high cutting speeds with low to

medium feed rates.

TiCN-Al O

2 3

P

Composition: Advanced CVD TiCN-Al O coating together with a newly engineered

2 3

tough carbide substrate. Ensures adequate deformation resistance and excellent M

Grade WU25CH edge strength and offers very good wear resistance over a wide range of K

machining conditions.

Application: A high productivity grade with high speeds and feeds. First choice

for high productivity with very good reliability in steels, stainless steels,

and cast iron rates.

TiCN-Al O

2 3

P

Composition: With a multilayered PVD TiN-TiAlN coating and a tough substrate, M

this grade withstands interruptions and provides high wear resistance for long tool life.

WU40PH Application: First choice for high reliability in most materials. This grade should be K

used at medium speeds and high feeds due to sharper edges and as a grade for high-

toughness applications. It covers steel, stainless steel, cast iron, and high-temp alloys

under certain conditions.

TiCN-Al O

2 3

P

K

WPK10CH

wear resistance P WU25CH

M

K

High-Speed Grade

P WPK10CH:

M

WU25CH:

K

WU40PH High Metal Removal Rate Grade

WU40PH:

High Toughness Grade

toughness

widia.com T7

10/29/15 1:12 PM

WID_Master16_Holemaking_IndexableDrills_T006_T007_Minch_REBRAND.indd 7 L V i WID M 16 H l ki I d bl Dill T006 T007 Mi h REBRANDO b 132015441PM