Page 1583 - Master Catalog 2017, Inch

P. 1583

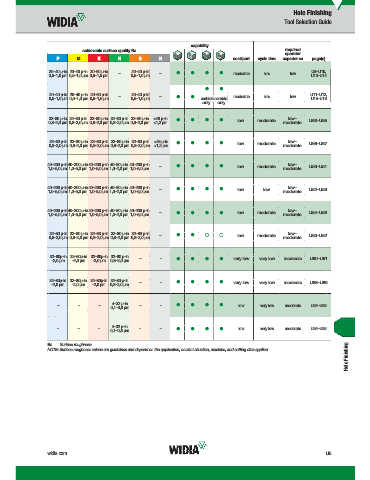

Hole Finishing

Tool Selection Guide

capability

achievable surface quality Ra required

operator

P M K N S H cost/part cycle time experience page(s)

20–40 μ-in 20–40 μ-in 20–60 μ-in 20–40 μ-in U8–U10,

0,5–1,0 μm 0,5–1,0 μm 0,5–1,5 μm – 0,5–1,0 μm – moderate low low U13–U14

20–40 μ-in 20–40 μ-in 20–60 μ-in – 20–40 μ-in – moderate low low U11–U12,

0,5–1,0 μm 0,5–1,0 μm 0,5–1,5 μm 0,5–1,0 μm carbide carbide U15–U16

only only

32–80 μ-in 32–80 μ-in 32–80 μ-in 32–80 μ-in 32–80 μ-in <48 μ-in low moderate low– U63–U65

0,8–2,0 μm 0,8–2,0 μm 0,8–2,0 μm 0,8–2,0 μm 0,8–2,0 μm <1,2 μm moderate

32–80 μ-in 32–80 μ-in 32–80 μ-in 32–80 μ-in 32–80 μ-in <48 μ-in low–

0,8–2,0 μm 0,8–2,0 μm 0,8–2,0 μm 0,8–2,0 μm 0,8–2,0 μm <1,2 μm low moderate moderate U66–U67

40–200 μ-in40–200 μ-in40–200 μ-in 40–80 μ-in 40–200 μ-in – low moderate low– U50–U51

1,0–5,0 μm 1,0–5,0 μm 1,0–5,0 μm 1,0–2,0 μm 1,0–5,0 μm moderate

40–200 μ-in40–200 μ-in40–200 μ-in 40–80 μ-in 40–200 μ-in low–

1,0–5,0 μm 1,0–5,0 μm 1,0–5,0 μm 1,0–2,0 μm 1,0–5,0 μm – low low moderate U52–U53

40–200 μ-in40–200 μ-in40–200 μ-in 40–80 μ-in 40–200 μ-in – low moderate low– U54–U59

1,0–5,0 μm 1,0–5,0 μm 1,0–5,0 μm 1,0–2,0 μm 1,0–5,0 μm moderate

32–80 μ-in 32–80 μ-in 32–80 μ-in 32–80 μ-in 32–80 μ-in low–

0,8–2,0 μm 0,8–2,0 μm 0,8–2,0 μm 0,8–2,0 μm 0,8–2,0 μm – low moderate moderate U60–U62

32–80μ-in 32–80μ-in 32–80μ-in 32–80 μ-in

-2,0 μm -2,0 μm -2,0 μm 0,8–2,0 μm – – very low very low moderate U90–U91

32–80μ-in 32–80μ-in 32–80μ-in 32–80 μ-in – – very low very low moderate U88–U89

-2,0 μm -2,0 μm -2,0 μm 0,8–2,0 μm

4–32 μ-in

– – – – – low very low moderate U94–U95

0,1–0,8 μm

4–32 μ-in

– – – – – low very low moderate U94–U95

0,1–0,8 μm

Ra Surface roughness

Hole Finishing

NOTE: Surface roughness values are guidelines and depend on the application, coolant situation, machine, and cutting data applied.

widia.com U5

11/10/15 12:06 PM

WID_Master16_Holemaking_Holefinishing_U004_U005_Minch_REBRAND.indd 5 L V i WID M 16 H l ki H l fi i hi U004 U005 Mi h REBRANDN b 1020151151AM