Page 180 - Master Catalog 2017, Inch

P. 180

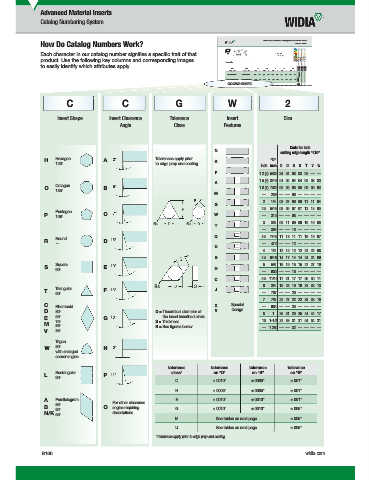

Advanced Material Inserts

Catalog Numbering System

Cubic Boron Nitride and Polycrystalline Diamond Inserts

How Do Catalog Numbers Work? ISO/ANSI Inserts

P

M

Each character in our catalog number signifi es a specifi c trait of that (C) first choice K N

alternate choice

S

product. Use the following key columns and corresponding images H

CCGW-C

D L10 S R D1

to easily identify which attributes apply. D L10 S R D1

ISO ANSI WBH10P WBH25P WBH30P WBK40U WDN00U WDN25U

catalog number catalog number mm in mm in mm in mm in mm in

3883561

CCGW060202EC CCGW21505EC 6,35 1/4 6,45 .254 2,38 3/32 0,2 .008 2,80 .110 – – – – –

CCGW060202S01015C CCGW21505S0415C 6,35 1/4 6,45 .254 2,38 3/32 0,2 .008 2,80 .110 3883505 – – – – –

CCGW21505EC

CCGW060204S01015C CCGW2151S0415C 6 35 1/4 6 45 254 2 38 3/32 0 4 016 2 80 110 3506 3573 – – – –

C C G W 2

Insert Shape Insert Clearance Tolerance Insert Size

Angle Class Features

Code for inch

N

cutting edge length “L10”

Hexagon Tolerances apply prior “D”

H A R

120° to edge prep and coating

inch inch C D R S T V W

F 1.2 (5) 5/32 S4 04 03 03 06 — —

1.5 (6) 3/16 04 05 04 04 08 08 S3

A

Octagon

O B 1.8 (7) 7/32 05 06 05 05 09 09 03

135°

M — .236 — — 06 — — — —

2 1/4 06 07 06 06 11 11 04

G

2.5 5/16 08 09 07 07 13 13 05

Pentagon

P C W — .315 — — 08 — — — —

108°

Rε Rε T 3 3/8 09 11 09 09 16 16 06

— .394 — — 10 — — — —

Q 3.5 7/16 11 13 11 11 19 19 07

Round

R D

— — .472 — — 12 — — — —

U

4 1/2 12 15 12 12 22 22 08

B 4.5 9/16 14 17 14 14 24 24 09

Square 5 5/8 16 19 15 15 27 27 10

S E H

90°

— .630 — — 16 — — — —

C 5.5 11/16 17 21 17 17 30 30 11

Rε 6 3/4 19 23 19 19 33 33 13

Triangular J

T F

60° — .787 — — 20 — — — —

7 7/8 22 27 22 22 38 38 15

C Rhomboid X Special — .984 — — 25 — — — —

D 80° D = Theoretical diameter of V Design 8 1 25 31 25 25 44 44 17

55° the insert inscribed circle

E G

75° S = Thickness 10 1-1/4 32 38 31 31 54 54 21

M 86° B = See fi gures below — 1.260 — — 32 — — — —

V 35°

Trigon

80°

W N

with enlarged

corner angles

tolerance tolerance tolerance tolerance

Rectangular class* on “D” on “B” on “S”

L P

90°

C ±.0010" ±.0005" ±.001"

H ±.0005" ±.0005" ±.001"

A Parallelogram For other clearance E ±.0010" ±.0010" ±.001"

85°

B O angles requiring G ±.0010" ±.0010" ±.005"

82°

N/K 55° descriptions.

M See tables on next page ±.005"

U See tables on next page ±.005"

*Tolerances apply prior to edge prep and coating.

B160 widia.com

V

B160 B161 Mi

16 T

WID M

i

i

I

L WID_Master16_Turning_Inserts_B160_B161_Minch_REBRAND.indd 160 h REBRAND N b 12 2015 2 22 PM 11/12/15 4:30 PM