Page 193 - Master Catalog 2017, Inch

P. 193

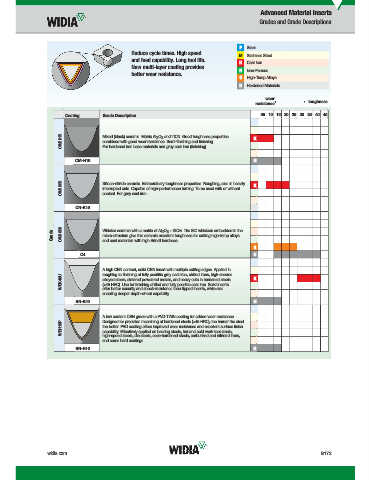

Advanced Material Inserts

Grades and Grade Descriptions

P Steel

Reduce cycle times. High speed

M Stainless Steel

and feed capability. Long tool life.

K Cast Iron

New multi-layer coating provides

N Non-Ferrous

better wear resistance.

S High-Temp Alloys

H Hardened Materials

wear

resistance toughness

Coating Grade Description 05 10 15 20 25 30 35 40 45

CW2015 Mixed (black) ceramic. Matrix Al O and TiCN. Good toughness properties K

2 3

combined with good wear resistance. Semi-fi nishing and fi nishing.

For hardened iron base materials and gray cast iron (fi nishing).

CM-H10 H

CW5025 Silicon-nitride ceramic. Extraordinary toughness properties. Roughing, also in heavily K

interrupted cuts. Capable of high-performance turning. To be used with or without

coolant. For gray cast iron.

CN-K15

Grade CW3020 Whisker ceramic with a matrix of Al O + SiCw. The SiC whiskers embedded in the

2 3

micro-structure give this ceramic excellent toughness for cutting high-temp alloys

and cast materials with high Brinell hardness.

S

C4 H

A high CBN content, solid CBN insert with multiple cutting edges. Applied in

roughing to fi nishing of fully pearlitic gray cast iron, chilled irons, high-chrome

WBK40U alloyed steels, sintered powdered metals, and heavy cuts in hardened steels K

(>45 HRC). Use for fi nishing chilled and fully pearlitic cast iron. Solid inserts

offer better security and shock-resistance than tipped inserts, while also

enabling deeper depth-of-cut capability.

BN-K40 H

A low content CBN grade with a PVD-TiAlN coating for added wear resistance.

Designed for precision machining of hardened steels (>45 HRC); the harder the steel

WBH10P the better. PVD coating offers improved wear resistance and excellent surface fi nish

capability. Effectively applied on bearing steels, hot and cold work tool steels,

high-speed steels, die steels, case-hardened steels, carburized and nitrided irons,

and some hard coatings.

BN-H10 H

widia.com B173

10/30/15 1:52 PM

WID_Master16_Turning_Inserts_B172_B173_Minch_REBRAND.indd 173 L V i WID M 16 T i I B172 B173 Mi h REBRANDO b 142015418PM